Nizhnekamskneftekhim's performance in 2018: rise in revenue, launch of new plants and financing of ethylene complex

Nizhnekamskneftekhim's sales revenue in 2018 rose by 27 billion rubles and was 189 billion rubles. The enterprise augmented sales volumes of rubbers and plastics and kept working to expand the assortment of products. Within an ecological programme, the backbone enterprise of the city is completing the second stage of reconstruction of biological treatment facilities. Last year, NKNK signed credit agreements with German banks to finance two big projects: an ethylene complex and its own power plant. More about the enterprise's performance in 2018 is in Realnoe Vremya's review.

Sales revenue increased by 27bn rubles

In 2018, Nizhnekamskneftekhim's financial indicators rapidly grew – sales revenue reached 189bn rubles, which is by 27bn rubles more than in 2017. The industrial production index totalled 103,2%. Rubbers and plastics remain key products for NKNK whose sales increased by 12,5bn rubles and were equal to 1,433m tonnes in total in volume. 716,000 tonnes of synthetic rubbers were sold – this is by 14,000 tonnes more than in 2017. The sales volume of plastics rose by 19,000 tonnes and reached 717,000 tonnes.

The enterprise not only augmented production volumes but also worked to expand the range of products. Last year, it mastered the production of bimodal polypropylene with unique physical and mechanical properties and new types of polystyrene for food packaging. In addition, NKNK offered Russian consumers medium-density polyethylene to manufacture big goods using rotomoulding technology. Previously, the need for this type of polyethylene was met only by imports. The work on new types of functionalised butadiene-styrene rubber and neodymium polybutadiene rubber went on to make premium tyres.

Nizhnekamskneftekhim in rubber market – economic environment in 2018

In 2018, Nizhnekamskneftekhim worked in a complicated situation in the synthetic rubber market. Brent crude's prices in 2018 rose by 14% since the beginning of the year, while butane's price increased by 29%, that of propane and butane mixture did by 31%.

Moreover, prices for ISR rubber made at Nizhnekamskneftekhim are based on natural rubber rates, which, on the contrary, tended downwards in 2018.

So natural rubber rates fell by 12% by September 2018 with a simultaneous rise in rates of the basic feedstock for ISR rubber – methanol by 16% and isobutene by 57%. The isoprene rubber production economics considerably got worse, but thanks the staff's well-coordinated work, Nizhnekamskneftekhim PJSC fully fulfilled its contractual obligations.

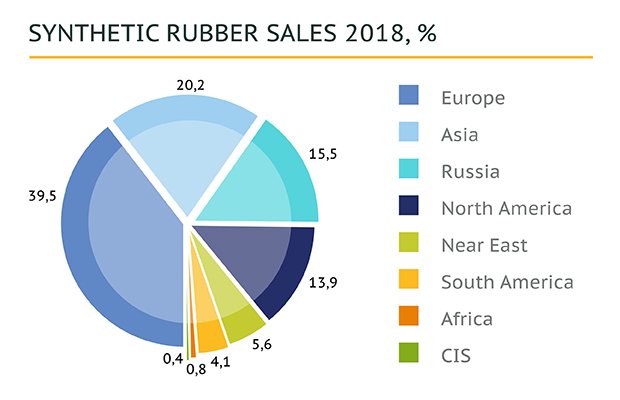

In 2018, rubber accounted for 41% of all sales of the company. 84% of 716,000 tonnes of synthetic rubbers were sold in foreign markets.

First medium-density polyethylene producer in Russia

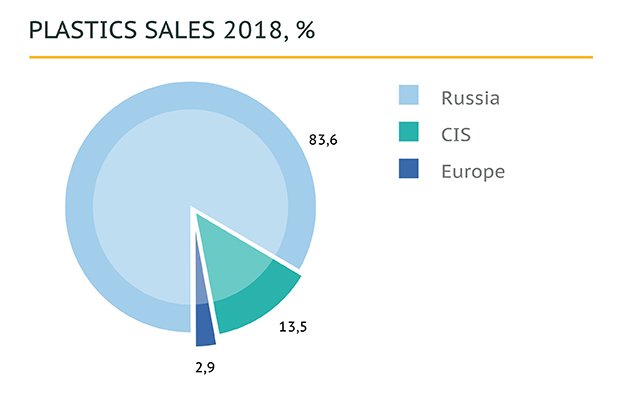

Plastics accounted for 33% of the company's sales in 2018. Moreover, almost 83,6% of plastics were sold in the domestic market, 13,5% in CIS countries and only 2,9% in Europe. Russia and CIS countries are a priority for the company. This is why Nizhnekamskneftekhim intends to increase sales volumes, including by expanding the range of products that are able to substitute imported analogues in the domestic market. Last year, Nizhnekamskneftekhim manufactured medium-density polyethylene to make large-sized articles by rotomoulding technology. It also mastered the production of bimodal polypropylene with unique physical and mechanical properties and new types of polystyrene for food packaging.

In accordance with May decrees of President of the Russian Federation Vladimir Putin on boosting the potential of import substitution, Nizhnekamskneftekhim annually tries to increase sales volumes of its own plastics in those segments of the domestic market where imported materials dominate. Thanks to the production and sale of Nizhnekamsk linear low-density polyethylene, the share of imports reduced almost 1,5 times: if in 2016 it was 75%, it became 52% in 2018. Moreover, the volume of polyethylene sales for anti-corrosion steel pipes with a big diameter increased by 82%. This is a relatively new but promising market for the company.

Modernisation and launch of new plants

In 2018, the company continued modernising and launching new plants. To reach 330,000 tonnes of ISR-3 isoprene rubber production volumes, an isobutylene plant with a capacity of 160,000 tonnes a year was put into operation in the isoprene monomer factory, the reconstruction of the isoprene factory also ended. Pre-investments in a new methanol plant construction project with a capacity of 500,000 tonnes a year began, methanol is a feedstock for formaldehyde production, which, in turn, is one of the raw materials in the ISR-3 isoprene rubber production chain.

Two SRT-VI highly efficient pyrolysis furnaces were put into operation in the ethylene plant, the reconstruction of the reactor of the 2 nd stage hydrogenation and the constructed of C6-C8 extraction and benzene emission block finished. This will not only allow increasing the capacity of the plants but also improve the effectiveness of processing.

The enterprise continued the implementation of a new styrene-butadiene rubber SBR plant project with a capacity of 60,000 tonnes a year, it's planned to complete the project in 2020.

The second stage of reconstruction of biological treatment facilities and new tank

The fourth ecological programme is carried out at Nizhnekamskneftekhim until 2020. Thanks to it, the enterprise reduced the volume of sewage by 2,45 million cubic metres, decreased emissions into the atmosphere by 469 tonnes and lowered non-disposable wastes by 5,080 tonnes in 2018 compared to 2017. The second stage of reconstruction of biological treatment facilities continued during the year where the mechanical treatment hub of chemically contaminated sewage was modernised. Sewage from Nizhnekamskneftekhim as well as from the rest of the industrial zone goes there – it's about 70 enterprises. This is why biofiltration was chosen to purify exhaust gases in the modernisation, which will reduce the impact on the environment, as it will allow preventing the emission of smells into the atmosphere. It's planned to complete the project this year.

What's more, in 2018, Nizhnekamskneftekhim began building a new tank for chemically contaminated sewage 15 km in length. It's an additional branch that will not only increase the capacity but also improve the safety of sewage transportation from the industrial site. The construction works are scheduled to end in autumn.

Flats for workers

A programme aimed to provide workers with flats goes on at Nizhnekamskneftekhim. Thanks to it, 3,559 families of petrochemists improved their living conditions with a mortgage programme, development of industrial complexes and an additional housing programme for TAIF GC workers since 2005. The enterprise continues participating in charity projects, supporting culture and sport. About 490 million rubles in total were sent to regional and urban programmes in 2018.

Financing of ethylene complex and its own power plant

The construction of a new ethylene complex with a capacity of 600,000 tonnes a year remains the key project of Nizhnekamskneftekhim. The issue of financing of the project was solved at the Petersburg International Economic Forum in May 2018. Five German banks thanks to the help of Euler Hermes export and credit agency will grant Nizhnekamskneftekhim €807 million until 2032 to implement it. Deutsche Bank AG is the key creditor, but money is also provided by UniCredit Bank AG, Bayerische Landesbank, Landesbank Baden-Württemberg, DZ BANK AG.

Nizhnekamskneftekhim also signed a €240m credit agreement with Deutsche Bank AG to build its own 495 MW power plant signed at the Russian Energy Week. Six German banks will give the money until 2033 – it's Deutsche Bank AG, UniCredit Bank AG, Bayerische Landesbank, Landesbank Baden-Württemberg, DZ BANK AG.

The ethylene complex project will allow the enterprise to achieve key indicators included in the strategic programme. By 2025, annual synthetic rubber production volumes are to augment to 1m tonnes, ethylene production – to 1,2m tonnes, while plastics production volumes are to grow to 1,5m tonnes.