About how a Belgian investor in Yelabuga joked about Putin's promise to grant Russian passport

Alabuga new projects: diapers from Europe and substrates made of mineral wool

Significant part of the working day of the president of Tatarstan on 13 September passed in Yelabuga. In the SEZ Alabuga he opened a plant of the Belgian company Drylock Technologies for production of sanitation and hygiene means and gave the start to the construction of a new plant for production of substrates of the already existing resident Rockwool-Volga LTD. Along the way, Rustam Minnikhanov held a meeting of the Supervisory Board of the SEZ Alabuga, where they considered and approved four projects at 9 billion rubles. Read the details in the report of a correspondent of Realnoe Vremya Yevgeniya Gazizova.

''They do not use them themselves but will recommend everyone to buy''

Drylock Technologies is a leading manufacturer and supplier of various hygiene products — absorbent underwear, diapers, special means for people with urological diseases. The company's plants are located in America and Europe. The plant in Yelabuga has become the second in Russia after the plant in Nizhny Novgorod. Drylock Technologies Ltd. received the status of a resident of Alabuga already in March 2013, but in 2014 the construction was halted. In 2015, the Belgian investor decided on resumption of the project. Then, Rustam Minnikhanov and Drylock Technologies CEO Bart Van Malderen celebrated the event by breaking a symbolic cube of ice. In the summer of 2016, the plant was put into operation. The president of Tatarstan, launching the new production, recalled the backstory of the events:

''It is a special object, it was started twice. The socio-political situation was such that we had to stop. But thanks to the desire of the investor we succeeded in implementing this project.''

The head of the republic highlighted that the new production is connected with import substitution, so these products need to be promoted, ''Here are Taliya Minullina, Albert Karimov. Of course, they themselves do not use them, but they will recommend everyone to buy. I'm kidding, of course,'' Rustam Minnikhanov relieved the deputy prime minister of the Republic of Tatarstan and the head of the Tatarstan Investment Developemnt Agency.

The president expressed gratitude to the Belgian investor who found not only money but also time to come to Tatarstan from Europe.

The founder and CEO of the Belgian holding Bart Van Malderen noted that if today someone from the audience did not use the product of his company yet, it was only a matter of time, because ''our products serves the entire life cycle of people.'' It is represented by three commodity groups: baby and adult diapers and feminine hygiene products. Their main consumers will become retailers, as well as hospitals and nursing homes. The outlet market will be not only Russia but also the countries of the Customs Union.

As the correspondent of Realnoe Vremya found out, the products are made not from cellulose but polymeric super sorbents by the company's patented environmentally friendly technologies. The company buys raw materials abroad in general, but in the future, local producers can become suppliers. In particular, it concerns Nizhnekamskneftekhim. Such negotiations are already underway.

The head of the Belgian holding also told jokes. He recalled about 40 million euros, which they invested in the new plant, and expressed confidence that now he could ask the president of the Russian Federation a Russian passport not only for himself but also for his son.

In the conversation with journalists, Bart Van Malderen told about other details of the investment project. The total production capacity is 3-3,5 billion units a year. Here, by the way, they differed in estimates with Rustam Minnikhanov, who called a smaller amount — about 433 million units a year. The plant already has about five installed lines and, according to the head of the Belgian holding, ''space for new ones remain''. Earlier it was reported that the plant is designed for 14 lines, which will be introduced into service gradually in several years until 2020.

The new production can be repaid in five years. It already has about 200 jobs, in the future this number can grow to 350-400.

Together with Rosatom

Before the foundation laying ceremony of the future plant for production of substrate of already operating resident of Alabuga, Rockwool-Volga Ltd., Rustam Minnikhanov had already managed to hold a meeting of the Supervisory Board of the SEZ Alabuga. They considered and approved investment projects of four potential residents with a total investment amount in establishment of new industries at more than 9 billion rubles.

In June of this year at St. Petersburg International Economic Forum, Director General of Rosatom Alexey Likhachev and Rustam Minnikhanov signed the agreement on construction in Alabuga of the plant for production of PAN precursor — the raw material for production of carbon fiber. In aircraft building, composite materials based on high strength carbon fibre are used in manufacture of structures of various aircraft equipment, including for critical power components, structures such as the wing, wing center section, keel, elements of mechanization, etc. In aerospace industry, from carbon composite they produce contsructions of heat shields of launch vehicles for various purposes.

The founder of the project, the company Khimprominzhiniring (part of Rosatom), expects that the capacity of the future plant will be 5,000 tonnes a year, 157 jobs will be created. The total investment amount is 6,9 billion rubles, 2,1 billion out of which will be invested by the SEZ Alabuga. It will provide a platform for construction, construction of buildings and structures, and the provision of energy for the period of operation. Rosatom will provide engineering, supply of technology and continued operation of production with the investment of 4,8 billion rubles. The start of production is scheduled in the 4th quarter of 2020. Over eight years, from 2017 to 2025, the investor expects to bring in the budget 2,7 billion rubles in taxes.

Khimprominzhiniring is the managing company of the division ''Advanced materials and technologies'' of the state corporation Rosatom. The purpose of its creation — the formation of the composite materials market in the country. It unites the scientific-research centre and enterprises manufacturing high strength and high modulus carbon fibers and fabrics based on them.

This is not the first project of the structure of Rosatom in Tatarstan. On the territory of the SEZ there is already operating Alabuga-Volokno PLC. The plant was launched into commercial operation in May 2015. The technology of carbon fibres obtaining was developed by Russian engineers. The production capacity is more than 1,400 tonnes a year. The potential of the new line is 2,000 tonnes of carbon fiber a year.

Fertilizers from the former oil refiner

The journalists were told about the next project by its initiator, Director General of Orgneftekhim-Holding Alexander Babynin. The Moscow holding company is the parent company of the group of 12 companies, ensuring implementation of full cycle projects in the refining and petrochemical industry — from developing of conceptual ideas, designing, construction, to the commissioning of a facility. The project on production of mineral fertilizers in Tatarstan will be implemented by INKO-TEK Agro Alabuga, part of the holding company. The estimated investment amount is 715 million rubles, the annual design capacity is 120,000 tonnes.

Alexander Babynin, which is known in Tatarstan as former head of TAIF-NK and the founder of INKO-TEK, intends to start in the region ''compound fertilizer production for specific cultures''. According to him, it can be ''components, of both chemical and organic properties — what a specific enterprise needs. Besides, what we do is just one segment of a large wheel, our concept of nature-forming technologies. The theme is strategic and secret, I will not reveal it for now, but in the future you will see that this is our first project in the large concept.''

According to the investor, the production is highly automated, only 50 people will work here.

As for raw materials for fertilizers, one of the variants can be carbamide, produced by located in Mendeleyevsk plant Ammonia. However, according to director general of Orgneftekhim-Holding, ''Ammonia is one of several potential suppliers'', despite the fact that Babynin is in the Board of Directors of the company.

The third approved project was the second phase of the plant for the production of sanitary and hygienic paper by a Turkish resident of Alabuga — the manufacturer of toilet paper, napkins and paper towels Hayat Kimya. The second phase will cost 3,32 billion rubles, and the total investment of the company will reach 9,5 billion rubles. The second phase will increase the production output from 65,000 to 140,000 tonnes per year. The launch is planned for the first quarter of 2019.

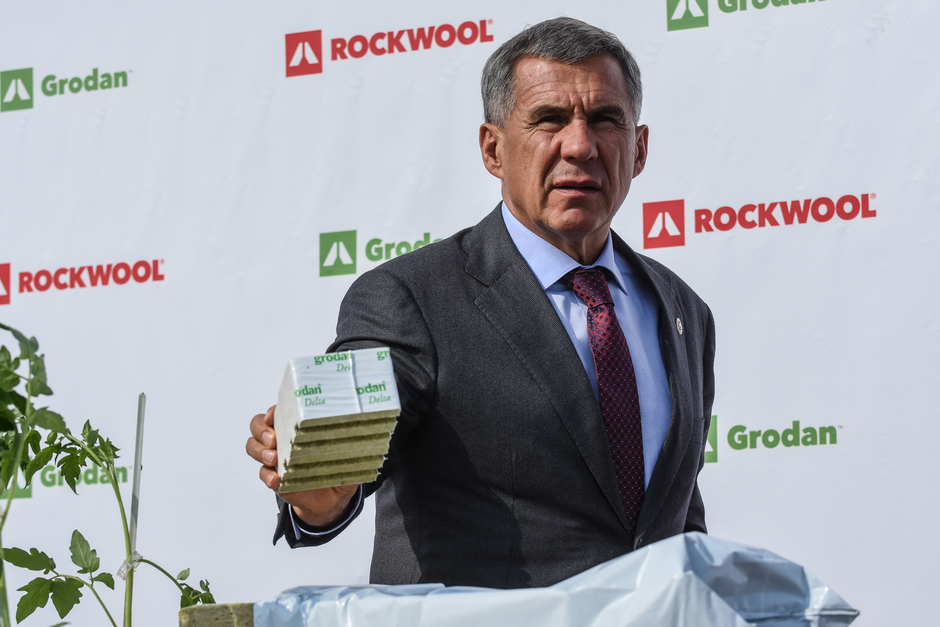

The fourth project under discussion, the construction of the plant Grodan for production of substrates made of mineral wool, was initiated by another current resident of SEZ Alabuga, the company Rocwool Russia. Rustam Minnikhanov came to the SEZ particularly for participation in the start of the construction of this plant. The new production is scheduled to launch on the land of already existing plant for the production of non-combustible insulation. The launch is planned for July 2018. The main consumers of substrates made of mineral wool are enterprises of the greenhouse crop production sector. The substrates are used in hydroponics, germination of seeds, growing of seedlings and plants. The substrate can act as an independent soil or as intermediate material. Grodan plant plans to produce a wide range of substrates, which are used in industrial agricultural production in all countries and in almost all crops, including tomato, cucumber, eggplant, pepper. The substrates are also suitable for cultivation of flowers — roses, gerberas, chrysanthemums, orchids. The capacity of the new production at the initial stage will amount to 4,000 tonnes per year with possible increase up to 8,000 tonnes. Managing director of Rockwool-Volga PLC Maxim Vasilyev said that today Rockwool supplies this product to Russia from their production facilities in Holland and Poland and the volume of the market is ''very promising''.

The volume of investments is estimated at 500 million rubles. This project is small, it will create 20 additional jobs.

Maksim Vasilyev reminded that out of 28 operating in the world factories of the corporation, 4 are located in Russia. The decision to locate in Tatarstan the new production was due to the success of the previous investment project.

Rustam Minnikhanov at the ceremony of laying the foundation stone of the new plant called Rockwool a strategic resident and expressed confidence that the new product is sure to be in demand not only in Tatarstan but also in Russia.