‘City within a city’: KNRTU students impressed by the scale of TAIF-NK production

Future chemical engineers have visited the Heavy Residue Conversion Complex and the biological wastewater treatment unit

Students of Kazan National Research Technical University (KNRTU) majoring in Chemical Technology and Oil and Gas Engineering took a tour of the Heavy Residue Conversion Complex. This facility is capable of processing up to 3.6 million tonnes of tar and vacuum gas oil per year into high-quality light petroleum products. Another stop on the route was the uniquely designed biological wastewater treatment unit. The young visitors learned about career prospects at the oil refining enterprise and witnessed how innovative technologies blend harmoniously with environmental care. Read more in the report by Realnoe Vremya.

“Shocked by the scale of the enterprise”

From Kazan to Nizhnekamsk, KNRTU students set off early in the morning and by 9:00 a.m. had already arrived at the administrative building of TAIF-NK JSC. They were first greeted by the occupational safety staff, who conducted a safety briefing and provided helmets and personal protective equipment.

Next, the students headed to the Heavy Residue Conversion Complex (HRCC). The tour was led by Ramzil Minigulov, Head of the Production and Technical Department. Ten years ago, he graduated from KNRTU himself with a degree in “Chemical Technologies of Carbon Materials Processing.” After receiving his diploma, he joined TAIF-NK as a process unit operator.

Learning this, the students immediately asked him what the secret to a successful career was.

“The path I took was not easy; it required diligence and hard work. The knowledge I gained at KNRTU played a key role. During my work, I improved my skills, delved deeper into technologies, and sought to understand every detail. I would advise those who wish to succeed to work persistently and to keep learning,” said Ramzil Minigulov confidently.

During the overview tour, the students saw the “inner workings” of the HRCC with their own eyes: the combined thermal hydrocracking unit, the fractionation unit, the sulfur production, the nitrogen and air production units, auxiliary shops, and the construction site of the future Research Centre. In the central control room, they spoke with process operators and shift supervisors.

Third-year student majoring in “Technology of Organic and Petrochemical Synthesis” Nikita Yakovlev bombarded refinery workers with questions and was reluctant to leave the control room — there was still so much he wanted to learn.

“Soon I will take part in university competitions where I will operate a process unit as an operator. The scale here is completely different compared to the simulators I usually train on. I also worked in Novocherkassk at a solar panel plant, monitoring a process unit, but it was much smaller. Here, I’m simply shocked by the size of the enterprise!” admitted Nikita.

Eyes and ears of the enterprise

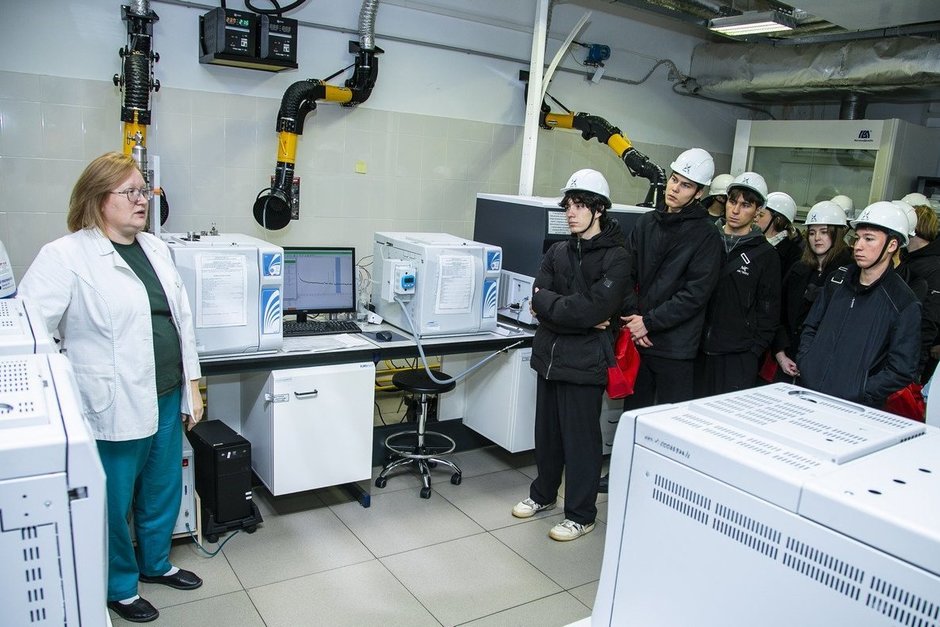

In the plant laboratory, the students observed the quality control process for both incoming raw materials and finished products. Thousands of samples are received here every month. The lab technicians study everything: raw materials, petroleum products, steam, gas, water, amine solutions, and much more.

“The laboratory is the eyes and ears of the enterprise. Each one is unique, tailored to a specific production process. We have all the necessary research equipment, including ICP spectrometers and chromatographs. There is also a coal preparation room — a facility that has no analogues at other refineries,” noted Head of the Laboratory Elena Demidova.

Incidentally, this was the second visit of KNRTU students to the HRCC. The first group of future chemical engineers toured the plant in December last year.

“We want students to understand that this is not just a plant but an entire system — a real city within a city! Everything here is interconnected, like in a metropolis. We also want to show the scale and features of our work. We have modern production, competitive salaries, and opportunities for career growth. The HRCC offers broad horizons for innovative and engineering ideas. We are currently building a Research Centre, which will strengthen our position among the world’s leading refineries,” emphasized Ramzil Minigulov.

Petroleum products — on the menu

The next stop on the route was the local biological wastewater treatment unit. Here, the students learned how environmental protection and production processes are closely linked.

The purification rate is 99.9 percent, and the plant’s capacity is 500 m³ per hour.

First, the wastewater undergoes mechanical treatment, where sand, sludge, and other solid particles are removed using special equipment. The second stage is flotation, where surfactants come into play. Acting like soap, they envelop micro-particles and lift them to the surface with the foam. The final stage is biological treatment, where voracious microorganisms do their work.

“It is a whole biocenosis of tiny living organisms that feed on petroleum products. There are aerobic and anaerobic bacteria. Each species of microorganism has its own role. To sustain them, an entire “zoo” is created in the aeration tank. At the inlet, the petroleum content is ten milligrams, and at the outlet — zero,” noted Ruslan Valeev.

“Get your degree and come to us”

After touring the wastewater treatment unit, the students returned to the main building of TAIF-NK JSC, where a hot lunch and a video presentation about the company awaited them. They were also shown samples of raw materials and finished products.

“The tour made a strong impression on me. Next semester, we will have our industrial internship, and TAIF-NK and Tatneft are the main companies to choose from. I noted several positive aspects about this enterprise: friendly staff, modern equipment, and impressive scale,” said Liana Demyanova, a third-year student at the KNRTU Institute of Oil, Chemistry, and Nanotechnology.

Her opinion was shared by future chemical engineer Anton Antonov from Sterlitamak.

“I was impressed by how interested the company’s management is in young specialists. They say directly: “Get your degree and come to us.” It gives me confidence that I’ll find a job after graduation. In the first year, we don’t yet have all the knowledge. Such tours help us better understand how production works,” said first-year KNRTU student Anton.

Head of the Department of Synthetic Rubber Technology at KNRTU, Tatyana Safiullina, emphasized that close cooperation between KNRTU and TAIF-NK helps solve production challenges and fosters mutually beneficial relations between science and industry.

“Our student community is quite diverse. The university has students not only from our republic but also from other regions — Bashkortostan, Chelyabinsk Region, Mari El, Chuvashia, Mordovia, and the Moscow Region. They see that Tatarstan is one of the leaders in oil refining in the country. Our graduates readily find employment at TAIF-NK, and students complete their pre-graduation internships here. Moreover, several TAIF-NK employees are currently postgraduate students in our department,” said Tatyana Safiullina.

TAIF-NK tours attract great interest not only from students of specialized universities and colleges but also from ordinary schoolchildren. According to company representatives, this was already the sixth behind-the-scenes tour of the refinery since the beginning of the year.

“During our tours, we talk in detail about the workers’ daily routines and the unique processes of deep oil refining. We aim to inspire young people to pursue engineering and technical professions so that they come to work with us. And we’re doing quite well at that,” said Anton Tukhvatullin, Head of the Training Group at TAIF-NK JSC.

No sooner had the refinery workers seen their guests off than new ones were already preparing to arrive — next in line are students of the N.V. Lemaev College of Petrochemistry and Oil Refining and pupils from the company’s sponsored School No. 10.