What one cannot do without…

A socially responsible business: projects bolstered and implemented by TAIF aimed to improve Tatarstan residents’ quality of life

A modern-time person got used to comforts that seem to be an indispensable and natural part of one’s life and doesn’t even think about where the comforts come from and thanks to whom. Read about who kept electrical energy and heating tariffs from growing in Tatarstan residents by paying for the difference, provided Nizhnekamsk citizens and Salavat Kupere Residential Complex residents clean drinking water and continues investing money in road construction in Realnoe Vremya’s cycle of reports dedicated to TAIF Group’s social investments. Part two.

Life energy

One of Tatarstan’s biggest energy companies — TGC-16 — was created in 2010 when TAIF Group purchased two CHPPs — Kazan CHPP No.3 and Nizhnekamsk Steam Boiler. Large-scale production modernisation started from the first days, which allowed ramping up the generation of both thermal and electrical energy at the highest capacity in a safe, effective and economic mode. Also, the CHPPS supply all types of energy to industrial factories of Kazan and the Kama Region, each on their own territory, they are also a reliable source of heat and energy in Tatarstan residents’ flats and houses and do their best to avoid a rise in price for energy.

Before TAIF Group obtained its own generation, enterprises that were part of it had already been carrying an additional financial burden for a long time by buying electrical and thermal energy for prices above the market price by keeping electrical energy and heating tariffs from growing for the population. This care didn’t stop even after the creation of TGC-16. From 1996 to 2014, nearly 80.7 billion rubles or, over $2.37 billion (at the average annual exchange rate), were allocated for these purposes.

And without water

“Neither here, no there,” as an old song puts it. Meanwhile, Nizhnekamsk — the republic’s third-biggest city — had to do without its own water intake area. Drinking water supplied from Naberezhnye Chelny was not enough either for people or factories. And the water that was supplied through old metal pipes and mixed with treated high-chlorine water left a lot to be desired in terms of its quality — a dirty slurry was running from the faucet, and at times there was none. The bad quality seriously influenced Nizhnekamsk citizens’ health and factories’ productivity. Up to 20-30 wells were drilled to fix the situation.

In 1996, the management of Nizhnekamsk made a decision to design and build its own water treatment facility. The works even started, near Ilyinka village but a deficit of funding and poor process organisation put the brake on the matter. In 1998, during one of the most economically difficult periods for Russia, with First Tatarstan President Mintimer Shaimiyev’s personal support and control, the problem of the shortage of clean drinking water in Nizhnekamsk started to be solved again. A decree of the Tatarstan Cabinet of Ministers On Renovation of 3rd Water Drilling Treatment Facility and Nizhnekamsk Water Supply System was issued on 28 January 1999.

Half of the country had to be visited learning already existing technologies and practical experience. Different speculators offered their “services”: trying to make money they persuade them to buy obsolete, inefficient, debatable technologies and equipment disguised as the latest developments. The first Tatarstan president’s support plays a huge role. Mintimer Shaimiyev, who chaired the Tatar ASSR Ministry of Land Improvement and Water in 1969-1983, was seriously intent on this issue and had a very good knowledge of water treatment technologies. TAIF’s proposal to create an absolutely new — combined — system uniting the best practices was approved in 1999. In March, Nizhnekamskneftekhim announced the development of a water treatment facility project with a capacity of 125.000 cubic metres a day. Specialists of a leading specialised research institute from Moscow Soyuzvodokanalproyekt of the Russian State Committee for Construction were entrusted with doing the works.

It was supposed the republican budget would allocate 40% of the money, and Nizhnekamsk enterprises and companies would divide the other 60% among each other. Nizhnekamskneftekhim was the client. In the end, most burden fell on NKNK’s shoulders. TAIF decided to mobilise every possible effort and money anyway do the task set by the republican management. Moreover, do everything properly.

The project entered its active phase in 2001. Up to half the staff of the oil refinery built the third lift of the water intake area and driveways to the would-be facility during the construction of the Water Treatment Facility — SOV-NKNK. 35 kilometres of underground pipelines connected nearly 30 overhead buildings of the facility with over 80 pieces of pump equipment and 12 sets of thin floc-forming units, devices measuring out reagents, sand and coal filters. Perhaps, only those directly involved in the water treatment facility’s construction and the management of TAIF Group know how much energy and money this took. The construction was constantly strictly controlled. Investments in key finds in the facility construction including major repairs over these years significantly surpassed not only its net profit but also money coming from production — that’s to say, money before tax deduction, depreciation and loan interest payment.

At the same time, staff training was underway. And also at the expense of TAIF Group.

The water treatment facility was solemnly launched in November 2007. First President of Tatarstan Mintimer Shaimiyev, then Vice Russian Government Chairman Sergey Ivanov, Plenipotentiary Representative of the Russian President in the Volga Region Alexander Konovalov, Russia’s Vice Minister of Industry and Energy Denis Manturov, Director General of TAIF JSC, Board Chairman of Nizhnekamskneftekhim PJSC Albert Shigabutdinov, NKNK Director General Vladimir Busygin, head of Nizhnekamsk Municipal District Aydar Metshin an dother attended the ceremony then.

“It is especially important to provide a good environment in such an industrial centre. I am very pleased that thanks to joint efforts of the federal government, republican authorities and, of course, private businesses, we designed such a modern, eco-friendly enterprise providing clean water. From now, all Nizhnekamsk citizens may not worry about what is running from this faucet when opening it,” noted Sergey Ivanov during the opening ceremony of the treatment facility in 2007.

The socially important project cost more than 2 billion rubles, most of the sum was invested by TAIF Group. At the same time, TAIF continued supporting the Water Treatment Facility later on: financially during the creation of the facility, heat and electrical energy, special feedstock needed for water treatment processes — which is tens of millions of rubles every year. Nearly 335.5 million rubles was allocated to subsidise water tariffs alone for the population. Works on the modernisation and maintenance of pipelines were done in Kazan too. In late 2017, a renovation of a pipeline supplying water to Kazanorgsintez PJSC and Salavat Kupere Residential Complex ended in the Tatarstan capital.

The old pipeline laid as early as 1962 already had sediment, turned out to have corrosion, accidents became frequent. The first two 820-mm pipelines leading to Kazanorgsintez were renovated in 2008. 3.300 metres of a 700-mm pipeline were replaced in 2016. Nearly 3.500 metres of the last part — supplying water to Salavat Kupere was substituted in 2017.

“The water pipelines laid on the territory of Kazan Helicopters 2 garden community, at the crossroads of railway and car roads couldn’t be dug. We use polymer hose rehabilitation in such difficult segments. The rust and foreign objects is removed from the pipe first by cleansing them with water under high pressure. After that, a robot with a camera is inserted in it, it goes along the route and films the pipe from the inside. Only then polymer pipe-based rehabilitation takes place,” head of the Shop of Treatment Facilities and External Communications of Kazanorgsintez PJSC Ildar Sayfutdinov explained the specifics of those works to Realnoe Vremya’s journalist. The total cost of these works is assessed at hundreds of millions of rubles.

Roads are life

It is useless to argue with this statement. Motorways connect cities, regions, countries, seas and continents. People run their errands and go to work using roads. Feedstock and equipment are delivered to factories and consumers are shipped end products by road. In other words, roads are arteries allowing the heart of the economy of any territory — its people and industry — to beat.

Some taxes collected in the country’s every region are used in construction, repair and maintenance of roads. Some think their mission of helping their own land is completed. However, TAIF always tries to do more.

In the early 21st century, there was a serious deficit of good road materials in Tatarstan. Concrete for road construction had to be delivered from other regions. The problem had to be solved in 2007 too. Road concrete production was launched at TAIF-NK JSC with the approval of the management and shareholders of TAIF JSC. Investments in the project amounted to 420 million rubles.

The installed capacity of this new unit is 120,000 tonnes a year fully met the republic’s needs for road concrete. Another unit producing high-quality materials for road construction — polymer bitumen binders with a capacity of 140,000 tonnes a year. For TAIF, concrete is far from being a profitable product. And after the launch of the Heavy Residues High Conversion Complex where tar is feedstock to produce high-quality light petrochemicals, its production could have been stopped, but the company doesn’t plan this.

“In Tatarstan, we are the only modern industrial factory that makes a wide range of concrete, we cannot refuse the commitment to the republic, its residents. Any road-relate investments have a long-term effect: the economy in general develops. The consumer simply won’t get our fuel without roads, so to speak,” Chief Engineer of TAIF-NK JSC Alexey Khramov told Realnoe Vremya in one of his interviews.

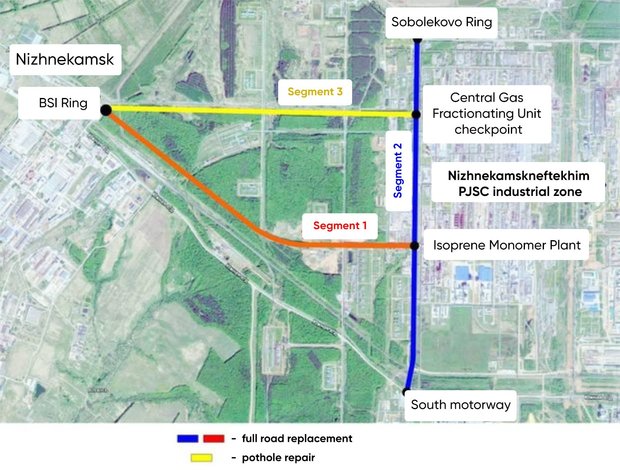

Social investments in the construction and repair of common roads, renovation of a 18-km road segment from Kotlovka village to the Heavy Residues High Conversion Complex, embankment improvement, repair of internal urban roads and improvement of nearby territories as well as repair of three segments of motorways connecting the city with the industrial site that are actively used not only by NKNK but also other big industrial enterprises in Nizhnekamsk alone surpassed 2 billion rubles.

The TAIF management repeatedly raised the issue of improving the logistics of the Kama agglomeration in general. The transport framework of the Kama Region — roads and railways and, most importantly, bridges — remained a legacy of the USSR, in fact, until recently. Today the situation is changing for the better. TAIF Group has both the merit and involvement in these processes.

People sometimes wait for the creation of quite a short but very necessary road, a real “life road” for them. And a business comes to the rescue. In 2019, villagers of Yelantovo, Nizhnekamsk District, received a present from TGC-16 JSC and TAIF Group in 2019. The settlement had been divided by the Sheshma River for 20 years. People had had to make a 3.5-km detour to get to school, kindergarten, hospital, bust stop, administration or rural centre. TAIF Group presented the villagers a new bridge.

“TAIF Group helps citizens of Nizhnekamsk District, Kazan and the republic a lot. This is why we shouldn’t say the construction of the bridge is a one time offer. This is just one of the small episodes of how TAIF Group operates,” Tatarstan State Council deputy Ruslan Gizzatullin (then vice director general of energy and information technologies at TAIF JSC) commented on the event.

TAIF Group’s companies invest considerable money in the creation and improvement of parks, squares and leisure areas. Read about this and much more in the next part of the cycle of reports.