Tatarstan diesel fuel turns 20 years

Two jubilees of Tatarstan diesel fuel production — one of the main products of TAIF JSC’s oil refinery

Tatarstan oil refining has had two jubilees in 202: it is the 20th anniversary of the launch of the Medium Distillate Hydrotreatment Facility at TAIF-NK JSC oil refinery, which started the production of diesel fuel in the republic, and the 10th jubilee of the transition of TAIF’s oil refinery to the production of Euro 5 diesel fuel. Read in Realnoe Vremya’s report about the stages of creation of diesel fuel production and if the sky is the limit.

Nearly 3 million tonnes of diesel fuel in 2021, the volumes have stayed in 2022

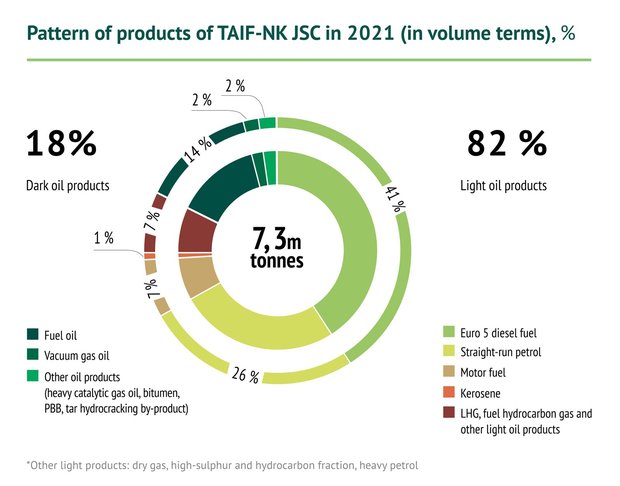

In 2021, TAIF-NK JSC produced 7,3 million tonnes of products. Nearly 3 million tonnes, or 41% of the total amount, is summer, all-season and winter diesel fuel.

Such numbers were voiced at a meeting with Tatarstan President Rustam Minnikhanov about TAIF GC’s financial and economic performance last year in August.

In 2022, even given the growing pressure of sanctions on Russia, diesel fuel output hasn’t decreased at TAIF-NK.

“Nowadays we reoriented the shipment of our diesel fuel to the domestic market by 24%. Production volumes are the same,” Director General of TAIF-NK JSC Maxim Novikov said in an interview with Realnoe Vremya during the recent TatOilExpo-2022 international forum.

Moreover, two new types of products were mastered in a niche where it seemed impossible to create something else: Euro 6 diesel fuel and Arctic diesel fuel.

The sky is the limit

“We issued our own technical terms based on the current standards but with stricter requirements for sulphur content in the fuel, it decreased twice: from 10 ppm to 5 (Editor’s note: ppm in Latin means pro pro mille, a millionth share, which is 1 ppm is 1 mg/kg of sulphur in a product). Humidity content reduced from 200 ppm to 100. Such indicators as polycyclic aromatics, oxidation stability, explosion temperature improved. All this allowed TAIF-NK to get an eco-friendlier fuel that has a better performance, reliable for the internal combustion engine significantly outperforming the requirements of the current standards,” Chief Engineer of TAIF-NK JSC Alexey Khramov told us about what Euro 6 diesel fuel was.

Euro 6 isn’t a product of the oil refinery but another unique plant of TAIF-NK — the Heavy Residues High Conversion Facility. As the plant admitted, it is rather an image-related product going ahead of its time.

“We can make fuel that not only complying with the state standard but considerable exceeding this requirement. It is our cue for the consumer saying that when using TAIF-NK’s fuel, you won’t have problems with the engine. Even in more modern and high-tech cars. As for the introduction of Euro 6 requirements at state level, I don’t yet have such information. As far as I concerned, this hasn’t been elaborated because Euro 5 is already the summit of how fuel can be treated,” noted Alexey Khramov.

However, we cannot help but note that the innovation hasn’t gone unnoticed at federal level. TAIF-NK Euro 6 interseason, E grade, K5 eco-friendly class fuel became a laureate of one of the most prestigious quality competitions in the country — 100 Best Products of Russia.”

“The low sulphur content in TAIF-NK Euro 6 diesel fuel allows reducing the opacity of exhaust gases, lowering sulphur oxide emissions and residues in the fuel system,” noted head of the laboratory in Shop No. 9 of the Heavy Residues High Conversion Facility of TAIF-NK JSC Yelena Demidova. Also, according to her, the innovation permits to significantly slow down the fuel injection system’s wear thanks to a low content of polycyclic aromatic hydrocarbons preventing deposits in spray nozzles, the combustion furnace and increasing the lifespan of the engine and at the same time reducing the cancerogenic danger of exhaust gases. Another advantage of TAIF-NK Euro 6 is lower oxidation stability, which allows expanding the integrity of diesel fuel’s initial characteristics. In other words, such fuel can be stored for a longer period.”

“The conversion facility made Euro 6, the oil refinery did Arctic fuel,” chief technologist of TAIF-NK JSC Alexey Taymanov talked about the second novelty. “Arctic fuel is a composite fuel with a set of special additives. It has improved characteristics in such indicators as cloud point and the maximum filtration temperature. I am sure the product will be in demand in northern regions of our country,” he added.

TAIF-NK’s commercial service is already actively creating contacts with potential of both the Arctic and another novelty, an intermediary diesel fuel between ordinary winter and Arctic fuel with up to 44°C of opacity temperature.”

“Russia is a huge country, and the regions of Siberia, the Far East, the North often store big amounts of fuel before the winter season. In other words, they bring fuel in summer and autumn and store it for winter, including diesel fuel. And of course, they choose the Arctic to avoid problems no matter the weather to provide all requirements for quality and be able to fill their equipment during the freezing cold weather. Nowadays we monitor the market and see demand for this product. We also see the demand for it at the Saint Petersburg Commodity Exchange,” Askar Sulteyev, head of the Commercial Department of TAIF-NK JSC, explained to Realnoe Vremya’s journalist.

From a feedstock are to modern facility: evolution in 20 years

TAIF was the first in Tatarstan to start thinking about the creation of a full-cycle oil refinery. ELOU AVT-7 unit that was rented and then purchased from Nizhnekamskneftekhim was its basis.

“It was built to provide Ethylene Plant with feedstock first, to get crude oil from straight-run petrol. In fact, it is fuel oil for the CHPP, and there was the full list of target products it made. The rest was a “by-product.” The unit itself was launched in 1978. But it was a completely different unit, not what we see today,” Director of the oil refinery Vladimir Lakhomov reminded us the history of TAIF-NK JSC. “The unit was repeatedly renovated: the capacity expanded, increased, the vacuum block, then the medium distillate hydrotreatment facility was built...”

“The construction and launch of then unique plant was back in 2002. It was the state-of-the-art equipment. This unit refined about 1,5 million tonnes of medium distillates making 2 000 ppm diesel fuel, which was considered low-sulphur then,” the chief engineer of TAIF-NK JSC continued.

Times went by, technologies developed, environmental requirements for motor fuel changed. Being proactive TAIF-NK continues upgrading its equipment. In 2008, together with Criterion Catalyst Co Ltd (Great Britain), the medium distillate hydrotreatment unit of the oil refinery was renovated, which allowed increasing the hydrotreatment catalyst’s volume by 10% and fully replacing the catalytic system. After that, TAIF-NK could produce Euro 4 diesel fuel. And equipment modernisation went on.

“The unit has been reconstructed and modernised since 2010. By June 2012, its productivity rose from previous 1,5 million tonnes to 2,3 million tonnes, while sulphur content reduced to 10 ppm. If those people who designed the Medium Distillate High Processing Facility in 2002 would have a look at it now, they would likely not recognise the unit. The catalyst content in the reactor increased repeatedly, an additional hydrotreatment reactor was installed, in other words, both the productivity and the sulphur treatment rate rose. The furnaces changed and were modernised. A vacuum column that allowed making a stable product was additionally installed,” Alexey Khramov briefly described the 10-year-long history of technology improvement.

TAIF-NK was the first in Russia to fully transfer its production to Euro 5 diesel fuel production complying with the strictest world standards. And this became a milestone not only in the history of the facility, TAIF Group and Tatarstan but also in the history of the oil refining sector of the country in general.

Delivering a speech at the launching ceremony, Tatarstan President Rustam Minnikhanov named this event a milestone for Tatarstan and all the Russian Federation. “There were many talks about the possibility of launching such production, and TAIF Group of Companies implemented this project at TAIF-NK quickly,” he noted before pressing a button together with Albert Shigabutdinov.

“For a better understanding,” the director of the oil refinery specified, “Euro 3 is 350 ppm in sulphur content, which is 350g per tonne. Euro 4 is 50g per tonne, no more. Euro 5 is no more than 10g per tonne. The remaining part of sulphur is removed in this facility. It becomes an independent product. Diesel fraction is made in the ELOU unit when separating oil, it is pumped into a tank and then goes to the conversion facility. And if the sulphur content in the tank is 1%, or 10,000 pp, in the facility, it is equal to 10 ppm. The sulphur content in diesel fuel reduces 1,000 times. Of course, fewer sulphur, nitrogen oxides, sulphur dioxide and other polluting substances are produced during the combustion in the car’s engine And all this lowers the environmental impact,” stressed Vladimir Lakhomov.

The oil refinery’s own central laboratory makes sure the technology is followed scrupulously and there is no complaint about the end product.

“Fuel quality control is provided at all the stages. From the incoming feedstock — oil used to make oil products, then semi-manufactured products are analysed, and everything through the products are examined one by one. Every stage has its own map, parameters a product must comply with. Laboratory examination is done according to these parameters,” notes head of the Central Laboratory of the oil refinery Margarita Urmanova.

20 years from a historical perspective is a short period of time. But for Tatarstan’s oil refinery is an era, a path from the full understanding that the republic playing a significant role in oil production nationwide simply must have its own oil refining to today’s TAIF-NK JSC, a modern oil refinery that can not only produce a wide range of popular products but also having leading positions in the country in such important indicators as crude hydrocarbon refining rate and the share of recovery of light oil products from it.

Ad. TAIF-NK JSC