German Leoni runs a risk of twofold increase of capacity in Chelny after two crises

One of the key residents Master Kama Industrial Park celebrated the 100 th jubilee in Naberezhnye Chelny. Representatives of the German company that manufactures wires and bundles supplied to Porsche, Renault, KAMAZ, Cammins and other companies was founded in 1917, at the height of WWI and Russian Revolution told Realnoe Vremya's reporter how the Chelny office successfully went through the second Russian crisis in a row and entered a new growth stage. Investments started to grow again, the staff number will double from 2016 to 2018. So the volume of investments in 2017-2018 will be 155 million rubles, which is 1,5 times more than the overall investments in 2013-2016.

From the Middle Ages to the UAE: how silver plate fabre production for the textile industry grew into an international holding

Important clients of Germany were presented on the jubilee of Leoni, which took place on Master KIP sites. The sites provided Germany with an opportunity to expand production twice: KAMAZ, KAMAZ-Master, Raritek. Technotron, Cummins, Daimler, Peugeot Citroën, Claas. Workers were making wires and bundles on a big territory that looked like structured long rows of shops without distracting for jubilees – it's a rare case when part of the work did not stop even for the official part (they are Germans, no need to add anything). It's curious that young girls are the majority of the staff. Indeed, one of the German workers noted that 75% of Leoni workers were women in both the Chelny factory and factories in other countries. An average track record of the Leoni workers in Chelny is 3,3 years, an average age is just 33 years. It's interesting thatб in fact, Leoni's history is 500 years old. The very name of the company is linked with the name of Leon. A young man who discovered production of gold and silver plated fibre for the textile industry came from this city to Nürnberg in 1569. In Germany, his company was called Leonisch. It is curious that the company stills manufactures gold and silver plated fibre. Clients from the United Arab Emirates where there is a high demand for such cloth are the main customers. In 1917, three families in Nürnberg united their efforts and officially created a factory to make top lace lingerie (!) but almost immediately started to produce wires.

It needs to be noted here the masters did not make electric wires but Leonische Waren (translated as ''Leon goods''), of course. Their name comes from León city in Spain and Lyon in France. In 1569, French-born Anthoni Fournier came to Nürnberg and opened the first Leonische Waren production – a very thin brass wire that was used to make wire mesh. Sieves for tea, coffee sieves made of this wire were famous in Middle Ages. Decorative goods made of silver and gold plated wire were sold as well as luxurious cloth with glowing metal surfaces – it was used in clothes of priests and expensive suits, which explains the clientele from the UAE. Leoni products were widely used to adorn New Year trees till 1920.

Leoni has raised sales volume 14 times in 25 years

Ralf Singmann, managing director of Leoni in Europe, started to work in the company more than 25 years ago. As an example of how fast time changes, he noted that his contract was typed on a typewriter, not computer. Then the annual sales volume of Leoni was DM 630 million (€320 million), today the sales have risen 14 times. In the 1950s, Leoni started to supply products to automobile factories and cooperate with Porsche whom it continues cooperating with today as well. However, at that moment, IBM was one of the most important clients of Leoni. Thanks to it, the Germans almost learnt how to manage the big business. When Singmann started to work, 1,500 people were working at Leoni, today – there are more than 80,000 people.

Leoni opened a factory in Tunisia in 1997 to reduce its costs. Then factories in Hungary, Slovakia, Poland opened then. Today most of the factories are outside Germany, particularly in Romania, Ukraine, Russia. American and Asian markets developed at the same time. When it became a holding in 1999, the company entered the Chinese market and opened the first factory there. Today they total six in the Celestial Kingdom. Leoni purchased factories from several rivals. Due to it, both new clients and new markets appeared: Bentley and Jaguar in England, Peugeot Citroën and Renault in France, Hyundai – in South Korea. And Renault Nissan became one of the main clients of Leoni's Russian division.

Production technologies developed during all this time: from usual bundles to wiring systems, antibacterial cables (needed in medicine), high voltage bundles (for e-cars).

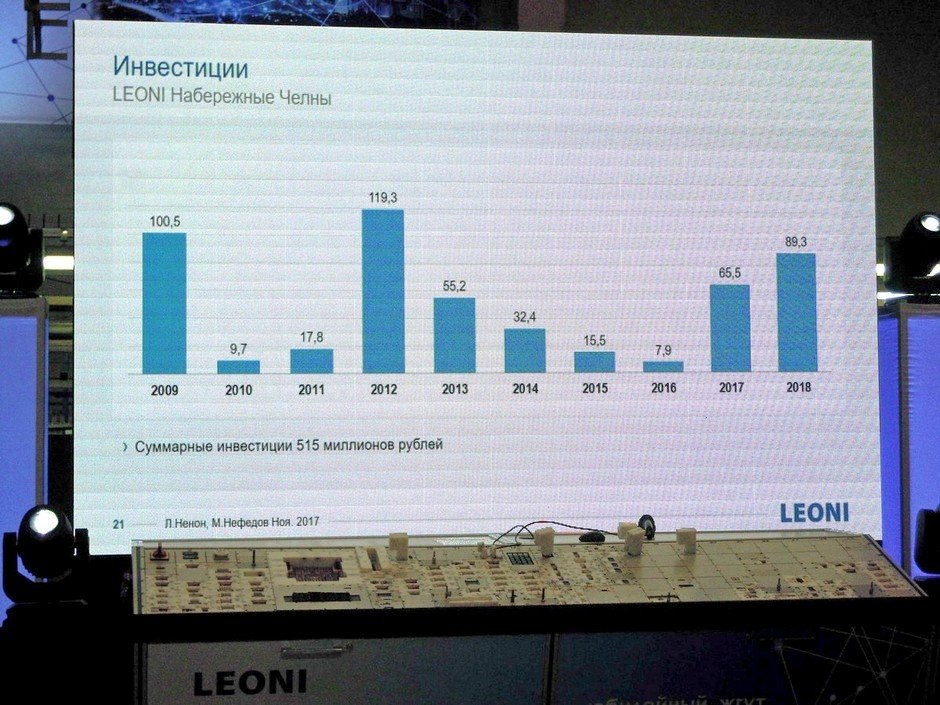

Germany has invested in the Tatarstan factory 515 million rubles in 9 years

Judging by his accent, Luc Nenon, director general of Leoni Rus CJSC, is French. The company can be really called international – Nenon is French, Singmann – German, and English is spoken in the company). He told that the sales volume of the holding in 2016 amounted to €4,4bn. The company opened its subdivision in Chelny in 2008. Germany has invested in the Tatarstan factory 515 million rubles in 9 years.

Nowadays 500 employees work in the Chelny enterprise and provide 8 clients with products. The company almost immediately became a partner of KAMAZ (it is still the biggest Russian client of the enterprise), Peugeot Citroën appeared in 2012, Class company became Leoni's client in Chelny in 2013. A merger of two juridical persons took place in 2014 – the factories in Zavolzhiye (Gorodets) and Naberezhnye Chelny united to establish synergy. Chelny's Leoni started to cooperate with RariTEK in 2015, Technotron in 2016. In 2017, Leoni started to collaborate with same KAMAZ on a new K-5 project.

The Germany company supplшies products to American Cummins in Chelny and will continue cooperating with it also in the production of heavy engines. Mikhail Nefedov, sales director at Leoni, noted that the Chelny factory provided Russian companies with products without depending on distance: for instance, PSA Peugeot Citroën is in Kaluga (1,100 km from Chelny), Claas is in Krasnodar (2,000 km from Chelny). The localisation level of bundle and wire factories is just 30% due to the small number of components in the Russian market. Wire factories have greater localisation.

Leoni's volume of investments started to grow together with a twofold rise in staff number

The company doesn't hide numbers of production volumes. However, according to the dynamics given by Nefedov, the highest sales were in 2012-2014, then they collapsed and started to go up again just in 2016. The company is going to achieve the indicators of 2013-2014 in 2018. Only the rise in the staff number speaks about the factory's development: if only 286 people worked in 2016, this year the number of staff workers is already 509. They're going to have 560 people in 2018.

The production dynamics directly correlate with investment volumes. 100,5 million rubles were invested to develop the factory in 2009, just 9,7 million in 2010, 17,8 million in 2011. The biggest investment was in 2012 – 119,3 million rubles. After that, the investment numbers annually fell (55,2m, 32,4m, 15,5m in 2013-2015) and reached the maximum in 2016 when 7,9 million rubles were invested. When the crisis peak was behind in 2017, the investment volume is to be 65,5m and 89,3m in 2018.

Chelny's city administration invited the Germans to become Priority Development Area, while Leoni supposes they don't fit criteria

Deputy director of the Executive Committee of Naberezhnye Chelny Natalia Kropotova who supervises the economic block of Nail Magdeyev was generous with praises of the Germans and admitted that the very city had to meet the requirements of Leoni that came to the city and ''increased the production level, rose the number of working places, strengthened market competition'':

''We're very glad that in 2017 Leoni set a goal to achieve the sales volume equal to €4,6bn, invest investments at €250m! Such a global player is right on our territory,'' Kropotova stated and seemed to be surprised at this shocking fact. ''Working places in this company are hi-tech and well paid: salaries here are a bit higher than in the city, in general.''

However, Natalia Kropotova focused on PDA in her speech. Having praised the foreigners, the functionary switched to diplomatic curtsies: like it would be great if Leoni also participated in this project:

''Naberezhnye Chelny became a priority development area. We're waiting for our investors! Today we're leaders in the Russian Federation in terms of the number of residents, we already have 16. New working places are created, investments are made… There are tax benefits for the investors,'' Kropotova was describing the participation in PDA in glowing colours. ''I'm addressing Leoni holding today: let's create a factory that will become a PDA resident. We hope a lot to have mutual good relations that we already have and will go on having.''

Number of workers to increase twofold after two crisis hits at Leoni since 2016

However, the representatives of very Leoni told us that the specifics of PDA presupposed development of a small and medium business, while the Chelny factory that 100% belonged to the foreign holding didn't belong to this category. However, Leoni will be glad to participate in any other state support programmes of Russia and Tatarstan. In answer to the question of Realnoe Vremya's reporter whether Leoni achieved target indicators in production and sales volumes that were installed while constructing the factory in Naberezhnye Chelny (in brief, whether the factory was profitable), Ralf Singmann admitted that the most difficult time for Leoni was during two crises that hit the business of the German company in Russia: in 2008-2009 and 2014 when the ruble rate suddenly fell against the dollar.

Mr Singmann said that they reached record volumes in the factory. They did not schedule any crises but had to work with it. He didn't name the turnover numbers but explained that he tried to use such indicators as working hours and staff number. So next year the company is going to increase the staff to 560 people by increasing production volumes. These digits are plans, while they hope to end 2018 with a big volume. If the economy continues growing and depending on the orders of their clients, they hope to reach 600 working places in 2018.