In spite of the crisis: how petrochemical giant of Tatarstan has managed to increase profits threefold

One of the biggest points of growth of economy of the Republic Nizhnekamskneftekhim PJSC amid the decline in industrial production in Russia is demonstrating decent financial indices and the dynamic growth of volumes of commodities. The annual revenue of the company has risen sharply up to 150 billion rubles, out of which 48% has been brought by export sales, where 78% belong to synthetic caoutchouc. What factors have become the guarantor of such outcome, learned the correspondent of Realnoe Vremya online newspaper, having studied the annual report of NKNK.

Domestic sales have exceeded export ones

In order to offset the negative impact of falling prices on world markets, the management of NKNH has decided to increase the volume of production and sales, to enter the economy mode — the tough control over expenditures of the company and the minimizing of non-production costs. As a result, taking into account the verified diversification of the caoutchouc and plastics production, stable supply with raw materials the company has managed to increase the output volume by 3.3% up to 2.4 million tonnes.

Accordingly, the revenue from the sale of these volumes has also increased — up to 150.6 billion rubles (for NKNK — up of 166.6 billion rubles) and became one of the main results of 2015 and the new financial record of Nizhnekamskneftekhim for its almost half-century history. Thus, the growth, according to simple mathematical calculations, has exceeded 13%.

Last year, as part of the development strategy, NKNH launched a number of new production facilities: the fourth unit of separation and drying of caoutchouc; an important technological hub on the isoprene-monomer plant, which will increase the production of isoprene rubber (SKI-3) almost by 15 000 tonnes per year; also it has been mastered the industrial production of new products – triisobutylaluminium, the catalyst of CDI-M and four types of plastics.

All these facts have strengthened more the company's position in the global and domestic markets. The implementation of the programme of import substitution also has brought the company significant results. In its framework, one of the significant projects has become the reconstruction of the production of linear alpha-olefins, the products will allow the company to abandon the procurement of imported raw materials in the form of butene and hexene.

Long-term contracts saved the sales of rubbers

For the world market, the 2015 year was marked by another decline in the cost of synthetic caoutchouc, the prices of which, in its turn, are determined by the market of natural rubbers. Since 2011 until the present time, the price of natural rubber has fallen four (!) times.

Nevertheless, the rubbers are traditionally the main export of commercial products of Nizhnekamskneftekhim, bringing a significant share of revenue. 2015 was also no exception. In the total share of revenue, 41.4% belongs to the rubbers. Besides, more than 90% of sales of synthetic rubbers belong to the foreign markets in 43 countries of the world.

What is more, more than 70% of the rubbers with NKNK brand due to long-term contracts are purchased by five world's leading tire companies. European processors of synthetic rubbers in the past year the company sent nearly 43% of the total share of export deliveries of these polymers.

This factor has provided the company with a reliable guarantee for the realization of this kind of product and helped to maintain a stable position of the enterprise in the conditions of unstable demand. As it is stated in the annual report of Nizhnekamskneftekhim, today the company's share in the global market of SKI-3 is equal to 43%, butyl rubbers — 16.2% of world volume.

A third of the revenue — on the account of plastics

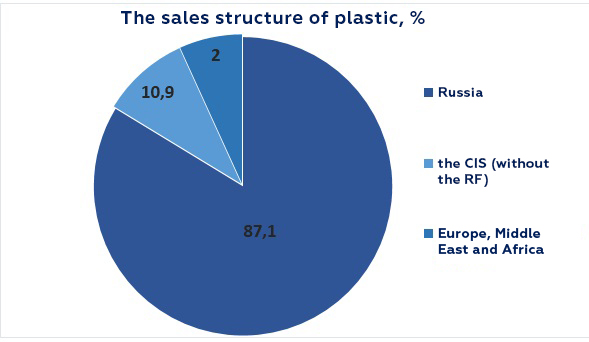

The situation on the market of plastics was more optimistic. The domestic demand for polystyrene plastics and polyolefins remained strong. These kinds of polymers accounted for the largest share of production volume realized within the Russian Federation, — 58%, and in the structure of revenues for plastics it accounted for almost 35%.

The total volume of polymers of styrene, ethylene and propylene at NKNK reached nearly 720 000 tonnes last year. The company is still the leader in manufacturing of polystyrenes and the only one in the country produces linear low-density polyethylene.

Thus, the volume of polyethylene and polypropylene production retained its last year's level, while the production of styrene plastics has increased by 2.5% to 305 000 tonnes. The work on the expansion of branded assortment has also become effective: the production of three new brands of polypropylene have been developed, polyethylene of the one brand which quality and the characteristics are not worse of their foreign counterparts.

By the way, last year in the structure of the main technological units there were integrated two plants — of polystyrene and polyolefins — and united in a single whole — the plant of plastics. The high quality of NKNK products and its large range of products were determining factors for the leading domestic processors of plastic raw materials — in the plastics sales structure the share of the domestic market in comparison with 2014 has increased by more than 3%. The sales of foreign manufacturers, including Near abroad, reached almost 13% last year.

As a result, the increase of production and sales of rubbers and plastics, including the production of import-substituting brands, has played a crucial role in the growth of gross profit up to 38.5 billion rubles. The company has the potential for further growth: according to the experts, the growth of consumption of plastics in Russia up to Western levels will be facilitated by the extension of the sphere of their application not only in industry but also in the construction, utilities and everyday life. For example, for each person in the EU and the USA it is from 100 to 130 kg of plastic per year, in Russia it is still only 50-60 kg per year.

The total amount of polymers — rubbers and plastics — produced by the petrochemical company of Nizhnekamsk in 2015, rose nearly by 2.5% to 1.4 million tonnes, which is more than a half of the total annual production volume.

Financial results

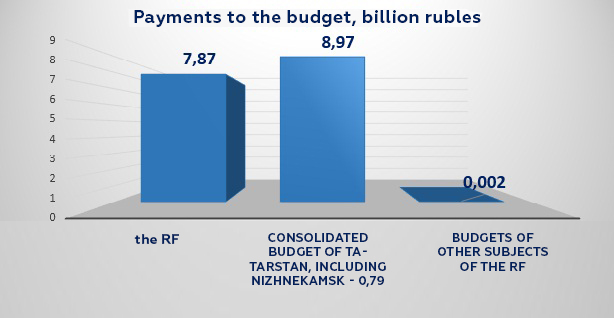

As for financial results, the net assets of the petrochemical giant of the Republic due to record revenues have increased by more than a third and by the end of 2015 amounted to 92 billion rubles. The growth of tax revenues to the budgets of all levels amounted to nearly 17 billion rubles, which is almost twofold more than the amount in 2014.

General financial and economic results of the year of NKNK are following: revenue from sales of products, having exceeded the previous indicate by more than 13%, amounted to 150.6 billion rubles. The production volume to the level of 2014 in comparable prices amounted to 103.1%. As for the current liabilities, the borrowings of NKNK decreased more than 2.7 times to 1.7 billion rubles in a year; taking into account the big amount of money and equivalents — nearly 12 billion rubles — has led to a negative net debt.

The reliability of the accounting report for 2015 was confirmed by the experts of the audit firm PricewaterhouseCoopers. As the outcome document states, the accounting report of NKNK 'accurately reflects the financial condition of Nizhnekamskneftekhim PJSC effective on 31 December 2015, the results of its financial and economic activities and money flows in 2015 in accordance with the rules of accounting statements reporting established in the Russian Federation'.

Billions — for social programmes

Along with the implementation of production tasks Nizhnekamskneftekhim implemented a number of social and other corporate programmes and projects. In 2015, in the framework of the fourth corporate environmental protection programme, 59 major events were performed at 740 million rubles. Its deployment helped NKNK in comparison with 2014 to reduce the emissions of pollutants into the atmosphere by 4.3%, by 2.5% — the withdrawal of water from Kama river for the needs of enterprises, and by 71% — the effluent discharge after buffer pond to the Strelochny Log brook.

Being one of the largest consumers of energy among industrial enterprises of Tatarstan, Nizhnekamskneftekhim continued to implement energy-saving measures, having saved 144 000 Gcal of heat energy, 24 million kWh of electricity and 2,000 tonnes of equivalent fuel at more than 187 million rubles.

Traditionally, the priority was to provide employees with housing. So, in 2015, petrochemical industry workers were allocated with 729 apartments, 235 of which were under the social mortgage programme and the development of industrial complexes; 494 apartments – additional housing construction programme, implemented for the employees of the companies joining the group of companies TAIF. For housing acquisition, the company provided its employees with 569 loans at 155.4 million rubles.

Besides, the company provides several social benefits for young people, women, pensioners, employees whose work is connected with harmful production factors. The total amount of NKNK on social and non-production expenses, accrued taxes in 2015 amounted to almost 20 billion rubles.

The future belongs to olefin complex

The main task of NKNH for the current year indicated in the annual report is the construction of a new olefin complex with a total capacity of 1.2 million tonnes of ethylene per year with an integrated production of polymers and other types of products that will allow increasing the output. As it is mentioned in the outcome document, Nizhnekamskneftekhim has already begun to implement the first phase of construction of the new olefins complex EP-600 and products for further processing.

The detailed business plan of the strategic programme of Nizhnekamskneftekhim development has been approved by the Board of Directors and adopted as the basis for the further work. They are working on the design of the first design stage. In addition to the implementation of this global project the company plans to increase the production capacities of synthetic rubbers, to continue the modernization and expansion of existing facilities for the production of monomers, and also to develop the technologies of production of import-substituting components. All these plans are in the comprehensive strategic programme of development by 2020.