How Kazan knife supplier to Shoigu dreams of becoming second Gillette

The owner of Melita-K with dreams of delicate razor blade business

Melita-K is famous for making unique knives across Russia and even abroad. The assortment surprises: from very hard knives to disposable scalpels. Now Boris Boguslavsky's company has focused on the production of blades for jet engines, but in the future, he dreams of locating a factory to make razors from which Gillette earns more than Boeing. Realnoe Vremya tells how prospective it is.

Heart valve replacement as first order

Melita-K СJSC was created in 1992 when the country made its first steps in entrepreneurship. Boris Boguslavsky's patents and developments in metalworking became the foundation for production. The candidate of technical sciences worked in the defence industry for many years, was the deputy head technologist in Sviyaga factory, which produced goods for the defence industry and medical equipment and collapsed in the early 2000s. However, Boris Boguslavsky left it long before its collapse.

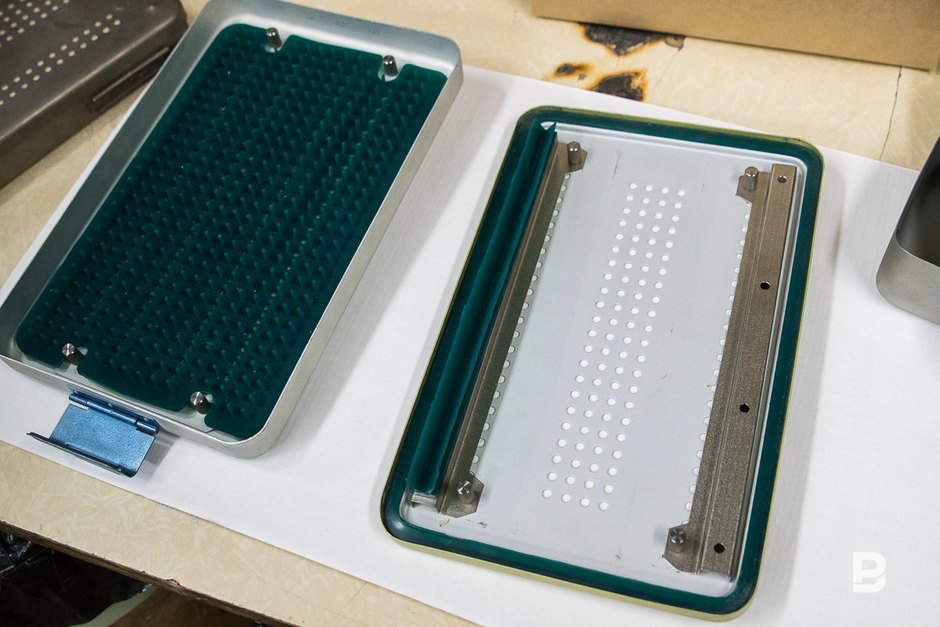

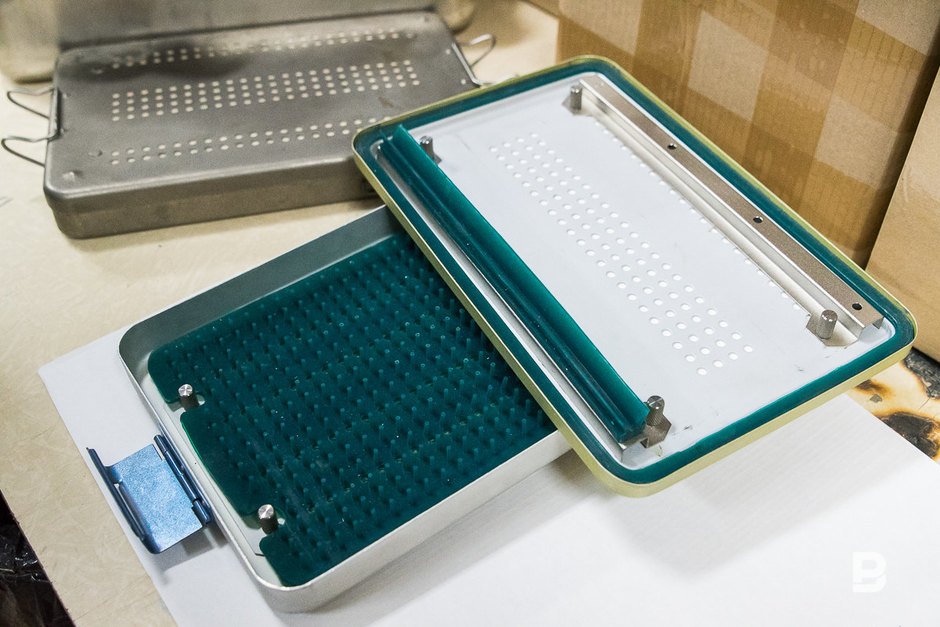

A heart valve replacement became the first important order in Boguslavsky's new business titled Melita-K.

''On a medical exhibition in Moscow, I acquainted with representatives of Electronic company from America that produces everything for heart surgeries. We offered to make a sample of the heart valve replacement according to our technology. They accepted,'' Boris Boguslavsky tells.

The valves were ready six months later, they were paid in the American currency. But cooperation with the foreign company ended when it switched to other types of valves that were based on a biological valve, not metal. Then Melita-K settled down in Khimgrad and concentrated on knife making.

How Melita-K provides army with knives

Knife making became one of the main areas of Melita-K, moreover, this market has changed little since the 90s. Boris Boguslavsky estimated there were still few enterprises who would make high-quality knives for butchers and kitchen workers. In the Soviet era, knives were made in Lenmyasomolmash Special Design Bureau factory. But after the dissolution of the Union, the factory lost its clients, as imported knives substituted Russian.

''Once meat factory workers turned to us and asked to make a good knife for them that would allow a butcher to process two tonnes of meat a day by separating it from bones. One can't provide such productivity with a blunt instrument,'' remembers Boris Boguslavsky.

Traditionally, the blade material is subjected to heat treatment and abrasive sharpening the grind and cutting edge. But during the milling process or use of an abrasive disc, the metal's properties worsen, the microstructure breaks. This is why Melita-K started to use the method of cold pressure metal working. First, the untempered material is subjected to cold deformation in a special device, as a result of which the knife gets a shape. Its structural characteristics improve with plastic deformation of steel because the metal's grain reduces in size. The knife's cutting edge is also forged by plastic deformation with the help of ultrasonic forging. Right this technology became the foundation to forge knives and medical scalpels later.

Melita-K's patented developments allow to create edges whose durability and wear-resistance excels the goods made according to the traditional technology.

The knives of Melita-K are made of different types of stainless steel and carbon steel. Their hardness is 58-60 by the Rockwell scale for carbon steel and 56-58 HRC for stainless steel. 60 HRC is considered to be the best indicator for a knife. If indicators are bigger than this point, the knife is hard but fragile. The majority of cutting edges have hardness from 52 to 58 HRC.

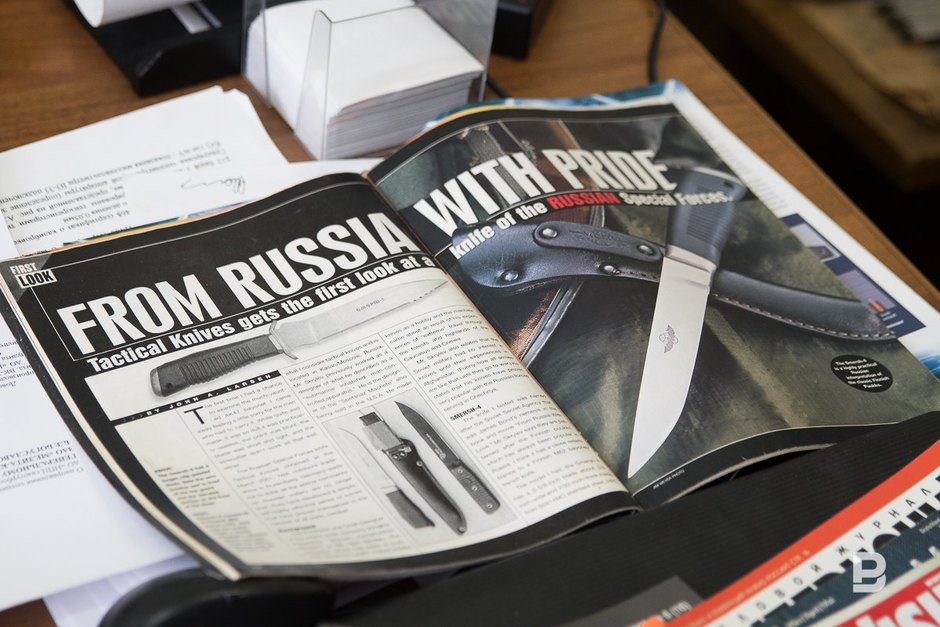

Melita-K mastered production of almost all types of knives: simple one-edged pocketknives, multifunctional pocketknives for different purposes, Finn knives, dive knives, combat knives, tourist and hunting knives, machete, support knives and self-defence knives.

Melita-K combat knives are in demand among Russia's force structures too. In 2005, the company presented Karatel combat knife to Russian President Vladimir Putin. FSB has sets of Melita-K knives, the army armed itself with it. Moreover, when the company tried to refuse to supply knives to the army (to focus on another assortment), a scandal broke out because other producers didn't have such products.

Government procurement accounts for 75-80% in production volume

If in 2014 knives accounted for the major share of turnover, now the share of knives is 5-7%. Part of the products goes abroad. For instance, windshield knives; Melita-K monthly exports 5-7 knives of this kind to Germany.

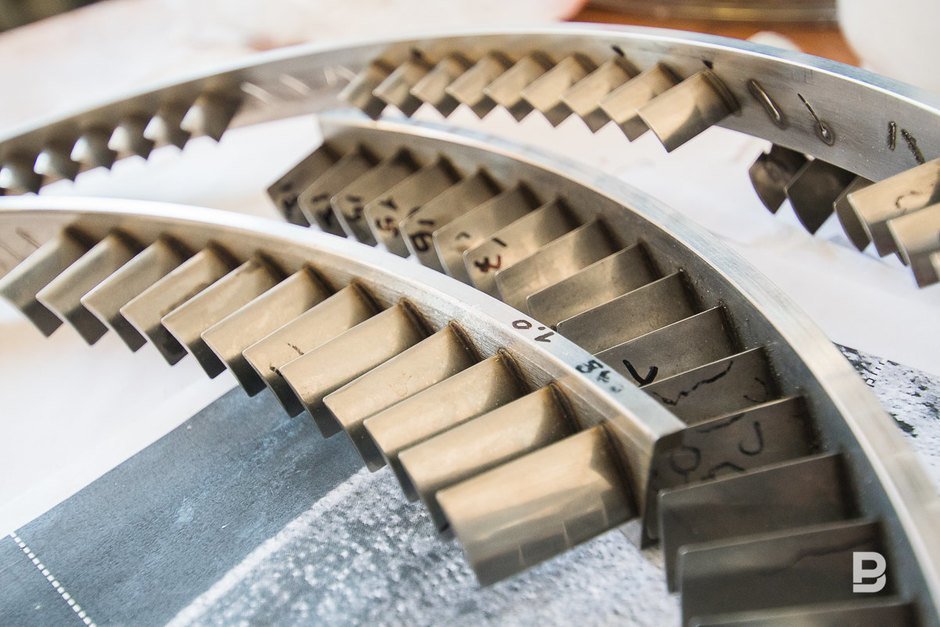

Now the company focuses one another thing – production of blades for jet engines.

''We stopped producing medical equipment and left a small number of knives. We have a small enterprise, we don't manage to deal with all procurement. We apply the technology we used to make knives and scalpels to produce blades for aviation, which are needed in engine making. We make separate components in the form of details, mounts for jet engines, the Klimov Design Bureau from Saint Petersburg orders them as well as their partner – Salyut Moscow engine plant. Now government procurement accounts for 75-80% of the volume of our products. We work for it.

We have a small enterprise, we don't manage to deal with all procurement. We apply the technology we used to make knives and scalpels to produce blades for aviation, which are needed in engine making

A blade in aviation is a very complicated task. According to the founder of Melita-K, it took 20 years of scrupulous work to master this technology, 14-15 years of them passed to achieve line production. The company makes small blades – the area doesn't allow to launch bigger production. Now the company is almost the only producer of this size of blades.

Razor blade as dream

The ultrasonic fording technology scored Melita-K a success. The company links its dream of creating a razor blade manufacturing factory with it as well. The quality of goods, which can be obtained thanks to this technology, doesn't lose to the quality that leading world producers of razor accessories achieve. But the task of creating a blade on the homeland is incredibly complicated.

''The thickness of a razor blade must be about 0,08 mm. To provide such sharpening, 0,01 mm of edges are cut from the plate four times,'' tells the entrepreneur.

There are only two companies in the world that make blades of such sharpening industrially – Gillette and Wilkinson. Gillette earns much more from such a little thing than Boeing Company making big planes, notices Boguslavsky.

The launch of razor blade production for Melita-K is also a matter of big financial investments.

''The country doesn't rush to invest to develop this technology, investors also look for projects with a short payback,'' complains Boris Boguslavsky.

Melita-K's technology was interesting for German Wilkinson. But the enterprise, which is sated with a billion turnover, doesn't see any sense in investing money to develop a new area to sharpen blades now. The Tatarstan company also tried to establish cooperation with ZWILLING J. A. Henckels, a company that makes knives and household appliances. Its representatives visited Melita-K's production shops. However, cooperation with this company didn't work out.

''They looked into us for a very long time but then concluded that they would have to substitute their old equipment with new to switch to our technologies. But it's not a fast process, while the company looked for the technologies that were easy to master. In the end, the Germans refused, and we stopped talking with them,'' tells Boris Boguslavsky.

According to him, Melita-K is famous not as a producer but a hi-tech developer. The company started its path with old equipment by gradually substituting it with modern. Melita-K still invests all money to develop, update machine tools.

''This is why we are among loss-making enterprises because all free money goes to improve the technologies and equipment,'' concludes Boris Boguslavsky.