Resource efficiency: what energy saving strategy of TAIF Group relies on

The diversified holding company presents its projects at an international exhibition

Rustam Minnikhanov has instructed the Tatarstan Cabinet of Ministers to address the issue of transferring heat supply from boilers to CHP. The president of Tatarstan came up with such proposal during a tour around the exhibition of the international energy exhibition 'Power Engineering. Resource Saving', which took place in Kazan and where the largest industrial companies, including TAIF Group, presented their projects. Read about the objectives of the large Russian holding in the material of Realnoe Vremya.

Nizhnekamskneftekhim saved 4,2 billion rubles on energy saving

The 19th international specialized exhibition 'Power Engineering. Resource Saving' finished in Kazan. The event was attended by leading energy and industrial companies. Among them there was the Tatarstan holding TAIF. The company's stand, which presented the most powerful enterprises of TAIF Group, was examined by President of Tatarstan Rustam Minnikhanov during a tour around the exhibition.

His started his tour from the stand of Nizhnekamskneftekhim, where the head of the company, Azat Bikmurzin, reported on the results of the energy saving programme of the company.

It is significant that the task to reduce energy consumption at Nizhnekamskneftekhim was set in 2000, even before the adoption of the federal and regional laws on energy saving. The company undertook the task thoroughly. They carried out the modernization and equipment replacement, implemented energy-efficient technologies. A total of 2,1 billion rubles was spent on the implementation of three energy saving programmes (2000-2015). But the impact was many times more. Over 15 years, it saved 5,8 million Gcal of heat, 347 million kWh of electric energy, 192,000 tonnes of reference fuel. In monetary terms, it is 4,2 billion rubles.

Currently, the company is implementing the fourth energy saving programme for 2016-2020. In total, the programme plans to save 31,6 million kWh of electricity and 605,000 Gcal of thermal energy, as well as 25,000 tonnes of reference fuel.

Energy saving implies not only resources saving, but also ensuring reliable and uninterrupted power supply. To do this, the enterprise carries out serious works. As a result, 167 old power control boards (SchSU-0,4 kV) were replaced with modern devices of the company Siemens. In total, it is planned to install 250 new power control boards and 27 distribution points and transformer substations.

The company introduced the complexes of high-speed automatic switch. In the event of a failure, they switch technological facilities to backup power supply, shutdowns do not threaten them.

It is possible to save the company's funds even on the heat carrier in the form of steam. In December 2013, dry return from the productions of Nizhnekamskneftekhim PJSC to Nizhnekamsk CHPP (PTC-1) (the branch of TGC-16 OJSC) was resumed. Over this period, the heat power plant received 8,51 million tonnes of return condensate, and the company saved on purchase of heat carrier.

Separately, the director general of Nizhnekamskneftekhim focused on the project for reconstruction of isoprene-monomer. Within its framework, the production of highly concentrated formaldehyde with a capacity of 100,000 tonnes per year was put into operation in 2017. This is the first of three projects under the programme of increasing the production of SKI-3 isoprene rubber to 330,000 tonnes per year. The programme will be fully implemented this year.

Competitiveness for the next 20 years

Then the government delegation moved to the stand of TGC-16 — the energy heart of TAIF Group. Director general of the company Eduard Galeyev told Rustam Minnikhanov about the results achieved by the company last year. Undoubtedly, the most breakthrough project in 2017 not only of TGC-16, but also of the republic as a whole, was the completed modernization of KCHPP-3. Eduard Galeyev for the first time announced the reasons why the energy company decided to take this step.

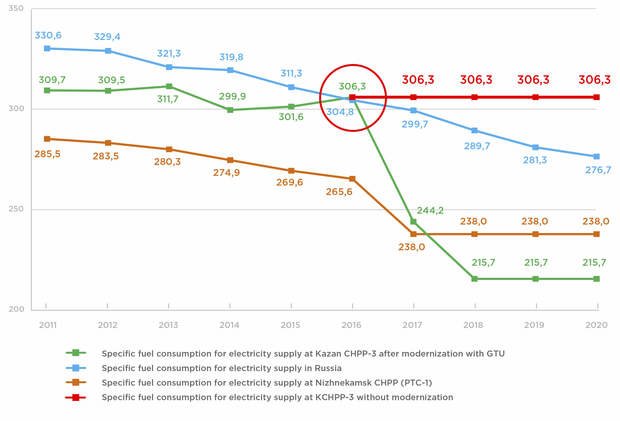

The issue of Kazan CHPP-3's modernization arose already in 2013, after the analysis of the dynamics of specific fuel consumption for electricity supply by KCHPP-3 and in general by energy sector of the Russian Federation. This parameter determines how much fuel the thermal station consumes to supply one kilowatt-hour of electricity. This figure can give the idea whether the station is competitive in the wholesale electricity market (WEM). According to the calculations of TGC-16's specialists, with the current dynamics of reduction in specific fuel consumption in Russian energy sector, Kazan CHPP-3 could have become uncompetitive already by 2016. And it is despite the fact that the station in comparison with other Kazan CHPPs has quite a decent amount of heat supply to consumers in combined cycle, among which the largest is Kazanorgsintez PJSC.

''For this reason, it was planned the complex modernization of the power plant, which was to provide its competitiveness in the wholesale electricity market and, at the same time, not to allow unacceptable for consumers rates for heat,'' Galeyev noticed.

The forecasts were fully confirmed. If in 2013 the average rate of specific fuel consumption in Russian energy sector was 321 g/kWh, then already in 2017 the average in Russia was 299,7 g/kWh, and by 2020 the ministry of energy of the Russian Federation predicts the figure of 276 g/kWh. The first results of KCHPP-3's modernization and its work in 2017 showed the correctness and timeliness of the decisions made — the average consumption of the station last year amounted to 244 g/kWh, that is, it decreased by almost 30% compared to 2016. This year, the average consumption rate of reference fuel at KCHPP-3 is planned at 215 g/kWh. Such fuel efficiency indicators will ensure the competitiveness of the power plant in the electricity market for the next 20 years at least.

Residents still do not receive cheap heat

According to Eduard Galeyev, today big energy is complaining about weak capacity utilization and low utilization of installed electricity capacity. The utilization rate characterizes the amount of equipment load of the stations under nominal conditions within a year. In this respect, TGC-16 managed to achieve excellent results. The utilization factor of installed capacity at KCHPP-3 increased by almost a third and amounted to 60% with 47% before the modernization of the power plant.

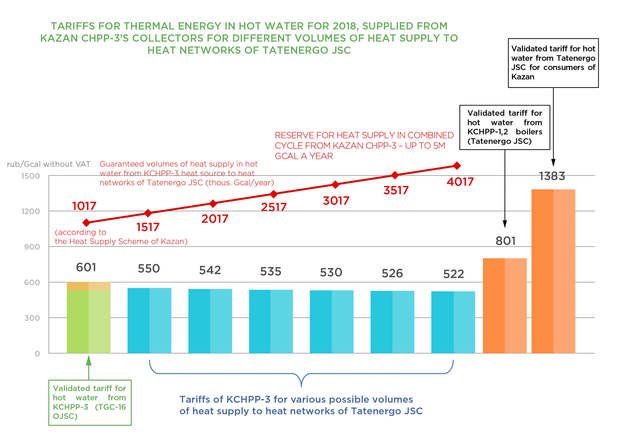

The most interesting thing is that all this was achieved against the background of extremely negative trends — reducing supply of heat and hot water in the network of Tatenergo JSC. As Galeyev told, compared to 2014, heat supply at KCHPP-3 decreased by 26%. In absolute terms, the heat supply in the network Tatenergo fell from 1,5 million Gcal to 700,000 Gcal, that is, in fact 2,5 times. Although TGC-16 has repeatedly announced its position, including in the media, that an increase in the load of KCHPP-3 will reduce the price for heating for consumers, primarily for the population.

As a proof of his words, Eduard Galeyev demonstrated to the president of Tatarstan the schedule of possible tariffs for consumers of KCHPP-3 depending on volumes of heat and hot water supply. The logic is simple: the more cheap heat will go from KCHPP-3 to the city, the lower the final tariff for residents will be. Here they again raised the issue that it is extremely necessary to take into account the interests of end users in the formation of the heat supply scheme of Kazan.

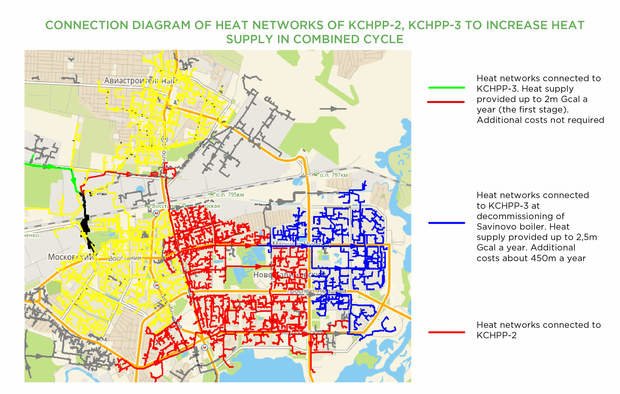

According to the calculations of TGC-16's experts, the scheme of heat supply should distribute loads so that to provide the maximum supply from cheap sources with combined production of thermal and electric energy, including from KCHPP-3, at the same time, the heat supply from boilers should be discontinued. The analysis was carried out on the basis of the electronic model of heat supply scheme, which was developed by specialists of the Kazan Energy University in the process of updating the heat supply scheme of Kazan.

''This distribution of loads does not provide for nothing new or revolutionary. In fact, such distribution and the discontinuation of the boiler house Savinovo with the transference of its load to KCHPP-3 was provided in the long-term plans of the power system already in the 1990s,'' said the director general of TGC-16.

He stressed that to solve this problem, the reconstruction and replacement of heating mains of Kazan with pipelines with highly efficient PUF insulation were invested large funds back when Ilshat Fardiev held the post of director general of Tatenergo. The losses during transportation of heat over such networks are not more than 5%. And it is not unfounded statements. TGC-16 experts raised the materials of plans of perspective development of heat networks and heat sources, which were developed at that time, and carried out their updating taking into account the new construction within the developed electronic model. Eduard Galeyev is sure that such scheme of connection of heat networks will help not only to save for consumers, to lower the tariff for heat, but also it will essentially increase reliability of the heat supply scheme. Because, for example, the boiler house Savinovo has no backup fuel, and the consumers will not be envied in the event of an accident in the gas supply system in winter.

Consumers pay about 200 million rubles from every billion of kilowatt-hours for electricity import

Rustam Minnikhanov supported the position of TGC-16. The president replied that he had personally been involved in this issue as head of the Tatarstan government and had set the task to solve the problem of discontinuing the boilers in Kazan and transferring their loads on the centralized heat supply system. Therefore, he expressed dissatisfaction with the fact that this work has not been accomplished yet. Also, Minnikhanov was interested in how much heat the boilers in Kazan supply, including the boilers of Kazenergo.

According to Galeyev, the figure fluctuates around 2 million Gcal a year, and taking into account the boilers of Tatenergo, it is up to 4,5 million Gcal a year. According to the assessments of TGC-16 specialists, the transfer of one million Gcal of heat from boilers to the generation in combined mode can additionally produce up to 700 million kWh of electricity. Considering that more than 4 million Gcal of heat were supplied from boilers in Kazan alone in 2017, it could be possible to produce additional 3 billion kWh of electricity.

''Due to this, the budgets of the Russian Federation and the Republic of Tatarstan received by about 260 million rubles of tax revenues less than they're due. In 2013 alone, the amount of unreceived tax revenues was almost 1,3 billion rubles,'' said Eduard Galeyev. It should be noted that in TAIF Group in the period from 2010 to 2013 all boilers were discontinued, and their thermal load in the annual volume of more than 1,8 million Gcal was transferred to the CHP for additional power generation. For this purpose, new heat pipelines were built, but it still has not been repaid.

The director general of TGC-16 also said that the problem of reduction of electricity generation in combined cycle has been particularly acute in recent years. In Tatarstan, the reason for this is that now due to a decrease in electricity generation by Tatenergo power plants because of the decrease in their competitiveness in the electricity market due to high specific fuel consumption, the republic is forced to import electricity externally. According to Grid Company's assessments, for each billion kilowatt-hours of imported electricity from outside of the Republic of Tatarstan, the consumers have to pay additionally up to 200 million rubles for its transportation through the networks of the Federal Grid Company (FGC).

''It turns out that a precious resource such as heat we do not use. Although it would be possible to significantly increase the competitiveness of power plants and to reduce the net power flows from outside of the region,'' Galeyev bitterly noted.

The problem voiced by the director general of TGC-16 seriously concerned the president of Tatarstan. As a result, at the government session, Rustam Minnikhanov instructed the Cabinet of Ministers to study the issue of maximum transfer of heat supply from boilers to sources with combined heat generation and to reflect it in the future within the framework of updating the Kazan heat supply scheme.

Prime Minister of Tatarstan Aleksey Pesoshin also expressed full solidarity with the president of Tatarstan. He noted that the main priority was to ensure the reliability and reduction of final tariffs for the population. It is the consistent position of the prime minister, which he voiced at the session of the committee on tariffs of the Republic of Tatarstan in January.

Energy supply costs of the HRCC amounted to 3 billion rubles

Other companies of TAIF Group also presented to Rustam Minnikhanov their projects in energy saving. So, Director General of TAIF-NK PSC Ruslan Shamgunov presented the approaches in the framework of the construction of the HRCC. Currently, the complex is completing the commissioning works and debugging of modes, the production of finished products has already been set up. Only advanced energy saving technologies are used in the production. All electric motors of medium and high power are equipped with high frequency wires or soft starters. The complex itself is connected to three sources of guaranteed power supply: Nizhnekamsk CHPP-1, the substation Nizhnekamskaya, the third source is the new 220 kV Begishevo substation built by Grid Company.

This is how the highest reliability of power supply of the new production is achieved. In general, the costs for the construction and commissioning of the system of internal and external power supply of the HRCC amounted to about 3 billion rubles. In the technological process the HRCC generates a large amount of heat. According to Shamgunov, it is used to the full, including for the drive of pumping equipment. For this purpose, steam turbine drives have been specially installed. The excess steam is returned to the single network of steam pipelines of TAIF-NK, where it is reused in its production. Thus, the maximum efficiency of using thermal energy and condensate of heating steam is ensured. Let us remind that the company, among other things, implements a waste-free scheme of recycling and industrial wastewater treatment. These activities after the completion of all commissioning works will make the HRCC at TAIF-NK one of the most environmentally friendly and high performance enterprises in the oil refining industry of Russia.

From the construction of furnaces to the new steam supply system of Kazanorgsintez

Director General of Kazanorgsintez PJSC Farid Minigulov presented Rustam Minnikhanov the two-chamber pyrolysis furnace Technip, the construction of which was started in 2013 to reduce energy consumption and to modernize the production of Kazanorgsintez PJSC. The furnace is part of the unit Ethylene-100. The unit Ethylene-100 is an integral part of the production of Ethylene-500, which refers to the ethylene production complex at Ethylene plant. The company plans to replace six pyrolysis furnaces, which have been in operation for more than 40 years and require significant investments to keep them in working order.

The preparatory works for the construction of the new two-chamber pyrolysis furnace began in 2013. Kazanorgsintez specialists considered the proposals of three leading global companies. The proposal of the Dutch company Technip Benelux was recognized as the most profitable and fastest in the implementation. The furnaces of this company were familiar to the company: since 2008, they had been used for the production of ethylene. In 2017, the two-chamber furnace Technip at the unit Ethylene-100 reached its design capacities. The investments in the construction amounted to 1,508 billion rubles.

The commissioning of the pyrolysis furnace Technip allowed to increase the production of ethylene, as well as provided additional production of own steam with the pressure of 30 atm up to 60 tonnes/hour through the use of sensible heat of pyrolysis.

Kazanorgsintez received the Grand Prix of the republican contest 'Energy efficient equipment and technologies' in the nomination 'Energy efficient developments' for optimization of the company's steam supply system at the 19th international specialized exhibition 'Power Engineering. Resource Saving 2018'. Presenting the results of the project to Rustam Minnikhanov during the tour around the exhibition, Director General of Kazanorgsintez Farid Minigulov noted:

''Reduction of energy consumption and resource consumption is one of the permanent tasks of petrochemists. We carry out this task according to the development programme untill 2020. At this exhibition, we present one specific project related to the pyrolysis furnace — the organization of steam supply. Now two furnaces are already working and another four are being under construction. Besides the fact that these furnaces save raw resources, they produce more steam, which we redirect to the plant network for domestic consumption. Thus, annually we save about 117 million rubles. Two furnaces give 60 tonnes of steam per hour, 15 tonnes of which are used for internal consumption of the enterprise, 45 tonnes goes to the plant network. The result of optimization of steam supply has become an increase in profitability of commodity products.''

''It turns out you also reduce the consumption from CHPP-3,'' said Rustam Minnikhanov.

''Actually, due to continuous increase in production volumes, the volume of consumption of thermal energy from the CHP has been permanent for already several years,'' Farid Minigulov answered him.

Later, at the government meeting, Tatarstan President Rustam Minnikhanov called the projects of TAIF Group in energy saving and improving energy efficiency as the energy potential of the republic.

''Today there are a large number of projects of TAIF Group at the expense of internal fuel resources,'' the leader of Tatarstan noted.

The natural result of the systematic work in the field of energy saving has become the created reliable foundation for development of the petrochemical complex of TAIF Group and the growth of production and financial results of its own energy division. Thus, the diversified holding has once again proved that with the right integrated approach to the activities of energy companies, when there is a constant, planned in detail and unconditionally executed work to improve technological processes, to reduce production costs, when it is rigidly set the task to ensure the interests and development plans of consumers as the priority, it is always possible to find huge reserves and opportunities for development and modernization of these enterprises. At the same time, TAIF always puts the priority on consumers, first of all, the population, without shifting the heavy burden on them in the form of unaffordable tariffs.