Russian crop to be cut by Sergey Kogogin’s Tatar-American engines

Despite a twofold production fall, Cummins Kama put a new engine assembly line into operation hoping for orders of agricultural producers

A new Cummins L engine assembly line was put into operation in Cummins Kama joint Russian-American company in Naberezhnye Chelny, which was created 11 years ago on the initiative of the car producer and Cummins Inc. As Realnoe Vremya's correspondent who visited the opening ceremony and talked to the top managers of both the joint enterprise and American concern, found out that production of the new and old engines depends and will depend on sales success of very KAMAZ. Despite the maximum capacity of engine production equal to 35,000 units per year, the summit was in 2012 when 12,000 units were assembled. Only 6,500 engines are planned for 2017.

Why Siberians avoid American engines

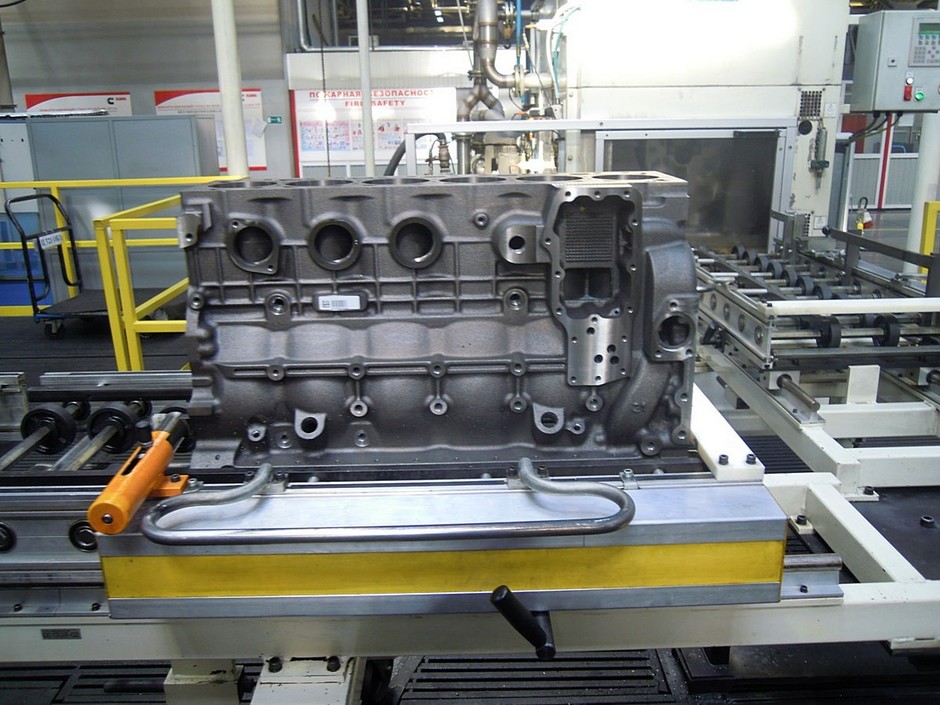

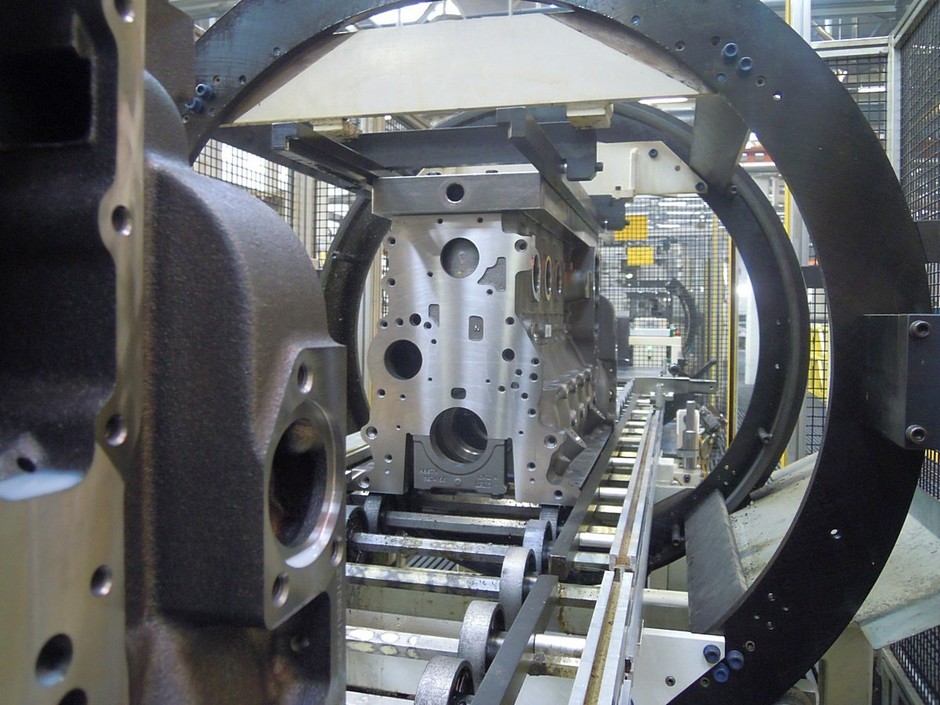

The joint enterprises of KAMAZ and Cummins Inc., which opened in 2006, has a production on the territory of Naberezhnye Chelny's industrial zone of 14,500 square metres. Four- and six-cylinder Cummins ISB and QSB engines are made here. A new series has appeared now. According to the press release, ISL engines will unite ''advantages of a light and compact engine with a structural integrity of heavy engines, provide high technical specifications while meeting high ecological requirements''. For instance, the engine with over 700 kg can be applied to trucks and medium-sized tractors used in Russian conditions. L engine family ''has already been applied to heavy trucks and КАМАZ-6520, vehicles produced by RIAT PJSC'', and localised version will be used in agricultural and off-road vehicles such as Rostselmash, Chetra bulldozers in the future. So, Cummins Kama joint venture will widen its assortment from March 2017 having put the assembly line of 8,9-litre engines of up to 400 h.p. into operation.

As Cummins Kama representatives told before opening of the line, nowadays KAMAZ PJSC were the key clients. Those KAMAZ vehicles where any buyer can put the Russian-American engines were standing at the entrance. KAMAZ -4308-R4, KAMAZ -65802, KAMAZ -65116», KAMAZ -65115, KAMAZ -6520-К4, KAMAZ -65117 and loader crane 658600 were among them. However, considering the digital filling of the engines and ''American capriciousness'' (and low quality of Russian fuel at times), Siberian clients prefer to buy trucks with Russian engines assembled in the KAMAZ engine factory.

The majority of Cummins engines are anyway made for the needs of the factory. Consequently, the joint venture's production volumes, first of all, depend on production and sale volumes of KAMAZ vehicles. It should be reminded that last year the factory sold 34,500 trucks, which is 21% more than in 2015. Curiously, very KAMAZ is going to assemble test samples of a new R6 (Euro 5) engine in summer 2017 and a test lot of over 200 engines by the end of the year. KAMAZ is going to launch a mass production of the new engines from 2019 – 12,000 units per year.

However, as KAMAZ PJSC press service head Oleg Afanasiev told the correspondent of Realnoe Vremya, at the moment, apart from the very car factory, the engines made by Cummins Kama joint venture were purchased by, for instance, Rostselmash. Afanasiev also assured that there would not be any competition between the KAMAZ engine factory and Cummins Kama due to different consumers. Moreover, 70% of the Chelny trucks have the KAMAZ engines if clients wish.

The joint venture works to only 1/6 of maximum capacity, and production volume reduced twofold within 3 years

KAMAZ PJSC deputy director general on development Irek Gumerov assured that today Cummins engines are used in the whole range of vehicles from 12 to 100 tonnes.

''In such a difficult period for our economy when the economy is not developing a lot, to put it mildly, anyway, we are making this step, we are investing in creation of the new engine,'' the KAMAZ top manager stated.

Cummins Kama CJSC director general Aleksey Polyakov noted that the new engine will ''cover the biggest power range – from 140 to 400 horsepower''. The maximum load of the Chelny line is 35,000 engines in a year now.

However, as the correspondent of Realnoe Vremya newspaper was told by the Assembly Shop director Viktor Kiploks later, the highest load of the enterprise was in 2014 when 12,000 engines were sold. We were said that just 6,500 engines are planned for 2017 (2,000 engines were already ordered). So, the joint venture works to only 1/6 of maximum capacity, and production volume reduced twofold within 3 years…

Mouldings from… Brazil: KAMAZ foundry is waiting for approval of American engineers

As for localisation, it won't affect the new engine. ''We set a bar of 3,000 engines a year when it is reasonable to start talks about a deep production localisation,'' Aleksey Polyakov admitted. In other words, localisation will directly depend on sales success and use by trucks and agricultural vehicles. Today localisation level of B engines excels 60% (production of engine blocks, block heads and crankshafts were localised). In 2017, the company will end localisation of piston and flywheel productions.

Interestingly, as head of one of the shops Rafael Shaidullin told during an excursion in the joint venture, at the moment Cummins Kama is working with mouldings from… Brazil. ''Are engines of the KAMAZ foundry bad?'' we asked. ''Brazilian mouldings are considered one of the best. The KAMAZ mouldings are at approval stage now. In any case, we will switch to KAMAZ mouldings, the localisation programme requires it,'' he promised.

''There were many changes in relations between the countries. But their relations with KAMAZ remained stable''

Cummins Inc. vice-president Steve Chapman who came to the Chelny land directly from the USA put the new line into operation. According to him, this May he will celebrate the 30 th anniversary of his first arrival to Naberezhnye Chelny, KAMAZ. Beaming with delight, the American recalled he discussed the possibility of granting a licence of American engine production and even production of L engines within a joint venture with KAMAZ representatives 30 years ago.

According to the vice president, there was a previous construction of the L engine, which was completely different. They continued negotiations on the joint venture with KAMAZ and created a concept of the joint venture during 20 years. The agreement on a 50/50 venture was signed in 2006. He also said they produce B and L engines throughout the world. Such producers as Paccard and DAF use L engines.

As Steve Chapman answered to a question of the Realnoe Vremya correspondent, Cummins engine sale has been quite stable in the last two years considering the existing instability in world markets. He said they managed to maintain the sales volumes and profitability level and hoped for further work on KAMAZ's success.

When we asked him whether colder relations between the two countries affected the business of Cummins and KAMAZ, he diplomatically replied that they treated both Russia and KAMAZ with deep respect. As he has been working here for 30 years, he said there were many changes in relations between the countries. But their relations with KAMAZ remained stable and even improved. Steve Chapman hoped this will continue.

The very joint venture told nowadays 230 people are working on its sites. And they can ''assemble 12,000 engines a year with this staff'' (considering the planned 6,500 engines, there are too many workers). What is more, the prime cost of production is expected to decrease together with the launch of the new engine. By calculations of the company, the launch of the new line will allow to increase the income by $1,2 million. L engines have already been ordered – the first lot of 10 engines is assembled today in the joint venture. Eight of them will go to Rostselmash (for combines) and two – to RIAT. In 2018, Rostselmash is expected to order 2,500 engines, RIAT – 500 engines and probably KAMAZ – another 500 units.